Wholesale Fine Calcined Alumina Powder - Low Sodium Calcined Alumina (CA) Series for Ceramics – Yufa

Wholesale Fine Calcined Alumina Powder - Low Sodium Calcined Alumina (CA) Series for Ceramics – Yufa Detail:

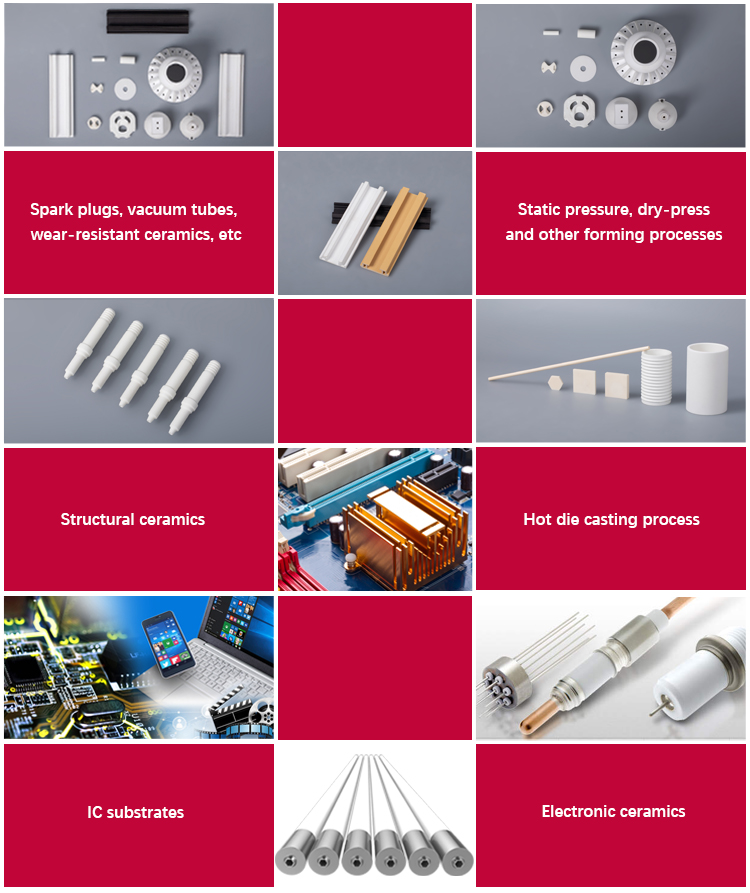

Applications

Specification

| Model No. | Chemical Composition(%) | True Density | Apparent Density | Grain Size D50 | +325 Mesh | Original Crystal D50 | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

<% | D50(μm) | |||

| CA1A | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.97 | >0.95 | ~70 | 5.0-6.0 | 1. High temperature calcination 2. Low sodium 3. Large crystal 4. High conversion rate 5. Stable shrinkage. Good fluidity 6. High insulation performance 7. High mechanical strength |

1. High-performance ceramics, such as vacuum tubes 2. Especially suitable for hot -pressing casting process |

|

| CA1D | 99.5 | 0.05 | 0.03 | 0.08 | 0.1 | 3.95 | >0.90 | 3.0-4.0 | 1. Low sodium 2. Moderate crystal size 3. Good particle size distribution 4. Small shrinkage and stability |

1. Spark plugs 2. Vacuum tubes 3. Wear-resistant ceramics, etc. 4. More suitable for static pressure, dry-pressing and other forming processes |

||

| CA1 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.95 | >0.90 | 3.0-3.8 | 1. Static kiln calcination 2. Low sodium 3. Moderate crystal size 4. Good particle size distribution 5. High porcelain density |

1. Mainly used in electronic ceramics 2. Especially suitable for Hot die casting process |

||

| CA2 | 99.5 | 0.08 | 0.03 | 0.08 | 0.1 | 3.96 | >0.90 | 2.8-3.8 | 1. Low sodium 2. Strict crystal size control 3. Good fluidity 4. Stable shrinkage |

1. Electronic ceramics, structural ceramics 2. Especially suitable for Hot die casting process |

||

| CA2G | 0.15 | >0.90 | 3.0-3.5 | < 3.0 | 1. CA2 full grinding 2. Particle size control stability 3. Low sodium 4. Shrinkage stability |

1. Electronic ceramics 2. Structural ceramics, more suitable for making ceramic rollers |

||||||

| CA3 | 99.5 | 0.05 | 0.03 | 0.04 | 0.1 | 3.96 | >0.85 | ~70 | 2.0-2.6 | 1. Strict control of firing temperature 2. Small crystal size 3. Good particle distribution 4. Pretty-low sodium |

Suitable for electronic ceramics, such as IC substrates | |

| CA3G | 0.1 | 2.4-2.9 | <1.0 | Fully grinding of CA3 | ||||||||

| CA4 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.93 | >0.90 | ~70 | 1.0-1.8 | 1. Good activity 2. Low sodium 3. High density after firing 4. Stable shrinkage 5. High mechanical strength |

1. Structural ceramics 2. Electronic ceramics 3. 99 alumina ceramic granulation powder material 4. Suitable for extrusion molding process as well |

|

| CA4G | 0.1 | >0.60 | 1.5-2.2 | <1.0 | Fully grinding of CA4 | |||||||

| CA5 | 99.5 | 0.05 | 0.02 | 0.05 | 0.1 | 3.92 | ~70 | <1.0 | 1. Small & unifrom crystal size 2. Good activity |

99 alumina ceramic hot die casting process, etc | ||

| CA5G | 1-1.3 | <1.0 | 1. Small & unifrom crystal size 2. Good activity 3. Fully grinding 4. Narrow particle size distribution |

Ceramic filter,etc | ||||||||

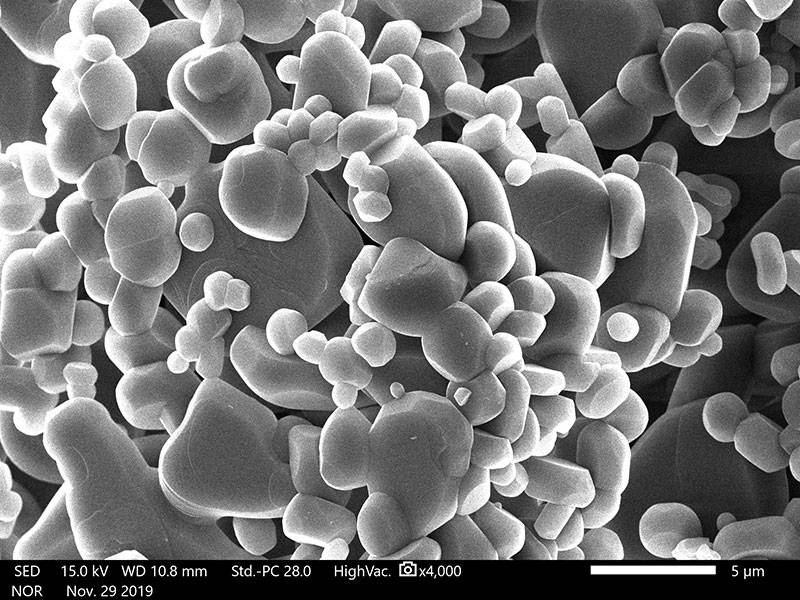

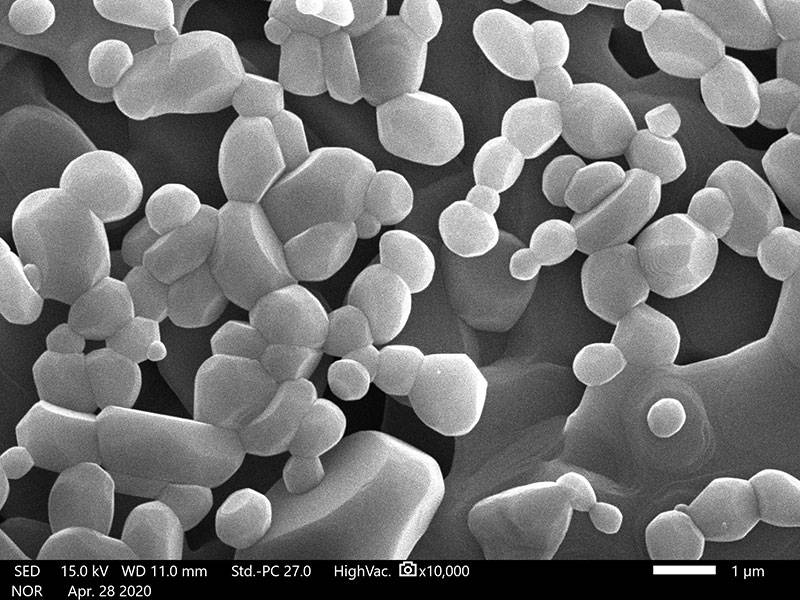

Product detail pictures:

Related Product Guide:

Our corporation insists all along the quality policy of "product top quality is base of organization survival; purchaser pleasure will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" plus the consistent purpose of "reputation very first, purchaser first" for Wholesale Fine Calcined Alumina Powder - Low Sodium Calcined Alumina (CA) Series for Ceramics – Yufa , The product will supply to all over the world, such as: Mexico, Eindhoven, Iceland, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We've been able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and items. For anyone who is interested in our company and products, be sure to make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are about to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please genuinely feel no cost to speak to us for enterprise. nd we believe we have been gonna share the most effective trading practical experience with all our merchants.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.

Write your message here and send it to us