-

Ready To Press (RTP)Alumina For Alumina Ceramics

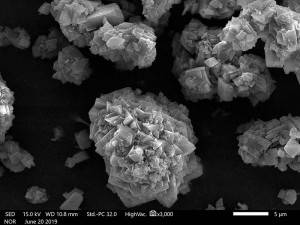

YUFA Group selects high purity alumina and suitable particle size, which uses pressure or centrifugal spray method to produce 92, 95, 99, 99.5 and other specs of Ready-To- Press Alumina/RTP Alumina(granulating powder). It is suitable for dry pressing, rapid stamping, isostatic pressing and other processes.

Features

1. Low ceramic forming temperature

2. Good powder consistency

3. High density, no pores in ceramic forming

-

Low-Sodium Calcined Alumina (HA) Series Coarse Powder

YUFA Group has invested a lot of technical research in the low-sodium alumina industry.

We have developed internationally advanced low-sodium technology in response to the needs of the low-sodium alumina market, which has effectively realized customization.

Features

1. Na2O content can be less than 0.01%

2. Suitable for various product applications

-

Calcined Alumina (FA) Series for Heat Conduction

Alumina has the advantages of heat conduction and insulation, and can be used as a thermally conductive filler for the preparation of thermally conductive insulating glue, potting glue and other polymer materials.

Thermally conductive alumina is a white powder crystal generated under high temperature conditions. There are many crystalline powders. The alumina used for thermal conductivity includes spherical alumina, quasi-spherical alumina, and composite alumina.

Features

1. Reasonable particle size distribution, high filling rate, low viscosity and good fluidity mixture can be obtained

2. High thermal conductivity, compared with crystalline silicon, the thermal conductivity of the mixture is high

3. Low abrasion rate: the appearance is spherical, and the abrasion of the mixer and the forming mold is small

4. The content of sodium and chlorine ion-like impurities is very small, and it has good electrical moisture resistance

-

Low-Sodium Calcined Alumina (SA) Series for Special Glasses

YUFA Group’s α-Alumina uses a unique calcined process and possesses the characteristics of high purity, low Fe2O3 content. It is the main raw material for LCD glass substrate and high aluminum cover glass.

Features:

1. High purity & ultra-low impurities.

2. High alpha phase conversion rate.

-

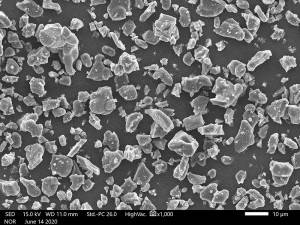

Low Sodium Calcined Alumina (CA) Series for Ceramics

YUFA Group can produce various ceramics alumina series which is suitable for hot die casting pressing, isostatic pressing, or dry pressing and other forming process.

Features

1. Low Sodium,which can below 0.1%.

2. High Purity Alumina

3. Crystal size can be customized

-

Brown fused alumina

Brown fused alumina is produced through the high-temperature smelting of bauxite in an electric arc furnace. Following the processes of raw material sorting, electrolytic smelting, crushing, ferromagnetic separation, screening, physical and chemical inspection, finished product packaging, and warehousing, brown fused alumina grinding is created. Brown corundum, derived from high-quality bauxite, undergoes refinement in an electric arc furnace at temperatures exceeding 2000 °C. Renowned for its exceptional purity, exquisite crystallization, remarkable fluidity, minimal linear expansion coefficient, and commendable resistance to corrosion, brown corundum proudly stands as the premier aggregate and filler for brown corundum refractories. -

Fused Mullite

Fused Mullite is manufactured by fusing a mixture of high purity Bayer Alumina and pure Quartz in a tilting type arc furnace at a temperature around 2000 deg C.

-

Calcined Alumina (RA) Series for Refractory Materials

YUFA Group has developed high-performance refractory calcined alumina based on its more than 30 years of production experience.

The calcined alumina refractory raw materials produced through the use of exclusive production technology and advanced rotary kiln and tunnel kiln equipment sell well in more than 40 overseas markets.

Features

1. With high bulk density, reduce the water consumption of unshaped refractories

2. The original crystal is small in size, has superior sintering activity and volume stability

3. Reduce or replace the amount of other ultra-fine powders and improve the high-temperature mechanical properties of refractories

-

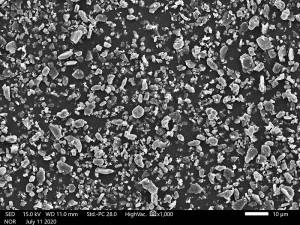

Calcined Alumina (PA) Series for Polishing

The Polishing calcined alumina are produced to different sizes based on customer's requirement. Series1. Fine polishing series:The original crystal is less than 1 μm 2. Medium polishing series 3. Special for rough polishing purple wax

-

Alumina Ceramic Products

YUFA Group also specializes in the production of spark plug ceramic insulators, porcelain tubes, oil well igniters and other products.Using isostatic pressing, high temperature sintering into ceramic. It can produce various spark plugs, ceramic tubes and other products with length less than 150 mm.

Features

1. High density

2. High strength

3. Good electrical resistance

4. Good size consistency

-

Monocrystalline Fused Alumina

Monocrystalline fused alumina, melting at high temperature by special process, is a high-end grinding material. The abrasive particles are off-white.

Features and Advantages:

1.Low sodium, below 0.2%

2.High hardness

3.High toughness

4.High bulk density and high wear resistance

5.High-end abrasive material

6.Small crystal, not easy to damage the workpiece

-

Fused Alumina Magnesia Spinel

Fused Alumina Magnesia Spinel is a new type of high-purity synthetic refractory material made from alumina and high-purity light-burned magnesia as the main raw materials in an electric tilting furnace after being melted at a high temperature of more than 2000 ℃ and then cooled.

Features

1. High bulk density

2. Strong erosion resistance

3. High corrosion resistance

4. Good slag resistance and seismic stability