PriceList for Reactive Alpha Alumina Powder - Low-Sodium Calcined Alumina (HA) Series Coarse Powder – Yufa

PriceList for Reactive Alpha Alumina Powder - Low-Sodium Calcined Alumina (HA) Series Coarse Powder – Yufa Detail:

Specification

| Model No. | Chemical Composition (%) | True Density | Apparent Density | Original Crystal | Conversion Rate | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

≥% | |||

| HA5 | 99.5 | 0.05 | 0.02 | 0.12 | 0.1 | 3.95 | 0.9 | 6.5-8.0 | 95 | 1. Unground & Low sodiume 2. Near-spherical crystal 3. Large crystal & Fully developed 4. Less shrinkage & Large output 5. Good quality stability |

1. Suitable for high-performance ceramics 2. Suitable for rough polishing 3. Suitable for refractory materials 4. Suitable for thermal conducting fillers 5. Suitable for wear-resistant coating industries |

| HA4 | 99.5 | 0.05 | 0.02 | 0.10 | 0.1 | 3.95 | 0.9 | 5.5-6.5 | |||

| HA3 | 99.5 | 0.05 | 0.02 | 0.12 | 0.1 | 3.95 | 0.9 | 4.5-5.6 | |||

| HA2 | 99.5 | 0.05 | 0.02 | 0.15 | 0.1 | 3.93 | 0.9 | 3.0-4.0 | 93 | 1. Unground, medium sodium 2. Near-spherical crystal 3. Crystal range of 2-3 μm 4. Good sinterability & Large output 5. Good quality stability. |

Suitable for ceramics and refractory industries. |

| HA1 | 99.7 | 0.05 | 0.02 | 0.01 | 0.1 | 3.93 | 0.9 | ~2 | 93 | 1. Extremely low impurities 2. Na2O≤ 0.01% 3. High conversion rate 4. Fine and uniform crystal |

1. Suitable for high-performance ceramics 2. Suitable for preparation of refractory powder 3. Suitable for wear-resistance coatings industries, etc. |

| HA2X | 99.5 | 0.10 | 0.02 | 0.08 | 0.1 | 3.95 | 0.9 | ~3 | 95 | 1. Easy to grind 2. Extremely low impurities 3. Good crystal sphericity 4. Narrow cystal distribution 5. Less shrinkage & Large output 6. Good quality stability |

1. Suitable for high-performance ceramics 2. Suitable for LCD glass, refractory materials 3. Suitable for thermally conductive fillers 4. Suitable for medium polishing materials industries, etc. |

| HA1X | 99.5 | 0.12 | 0.02 | 0.10 | 0.1 | 3.93 | 0.9 | ~2.3 | 93 | 1. Easy to grind & Low sodium 2. Good sphericity 3. Narrow cystal distribution 4. Small crystal & Good flowability 5. Large output & Good quality stability |

1. Suitable for the production of high-performance ceramics and refractory fine powder 2. It can be used in alumina ball |

| HA0X | 99.5 | 0.08 | 0.02 | 0.10 | 0.1 | 3.9 | 0.9 | ~1 | 92 | 1. Small crystal 2. Low impurities. |

1. Suitable for the production of high-performance ceramics and refractory powder preparation 2. It can used to preparation of wear-resistant coatings industries, etc 3. It can be used in alumina ball |

Application

1. Suitable for high-performance ceramics, rough polishing, refractory materials, thermal conducting fillers and wear-resistant coating industries

2. Suitable for preparation of refractory powder etc.

3. Suitable for LCD glass, thermally conductive fillers, medium polishing materials industries, etc.

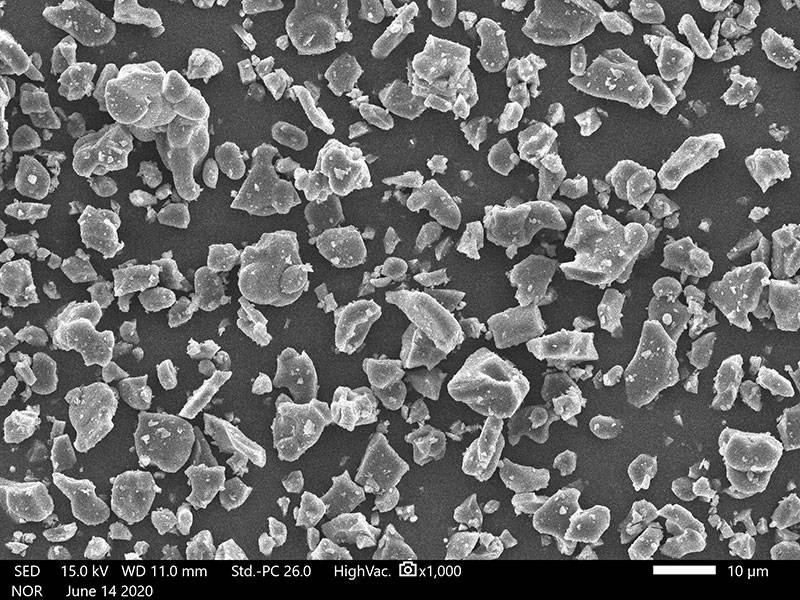

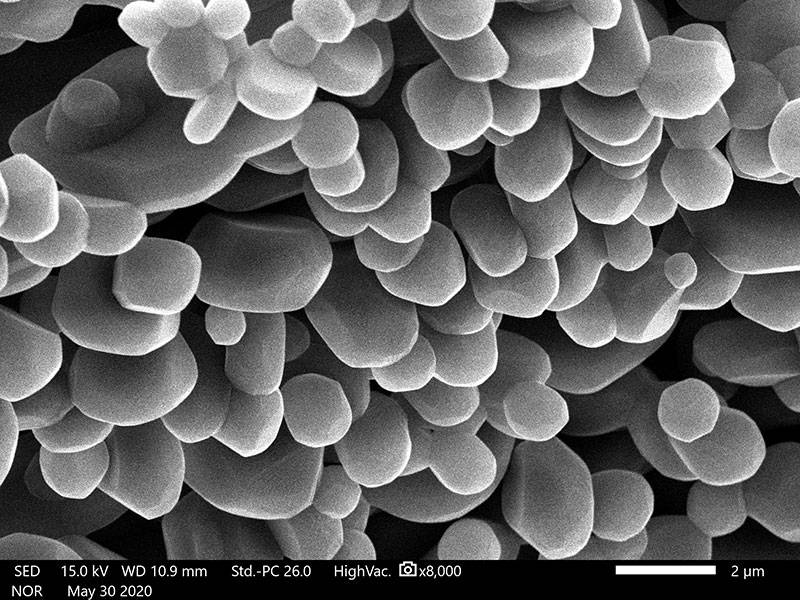

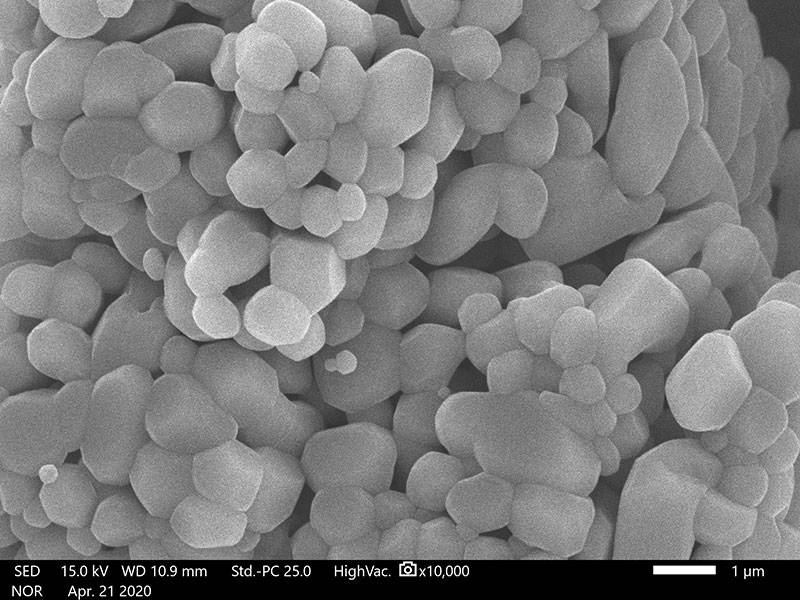

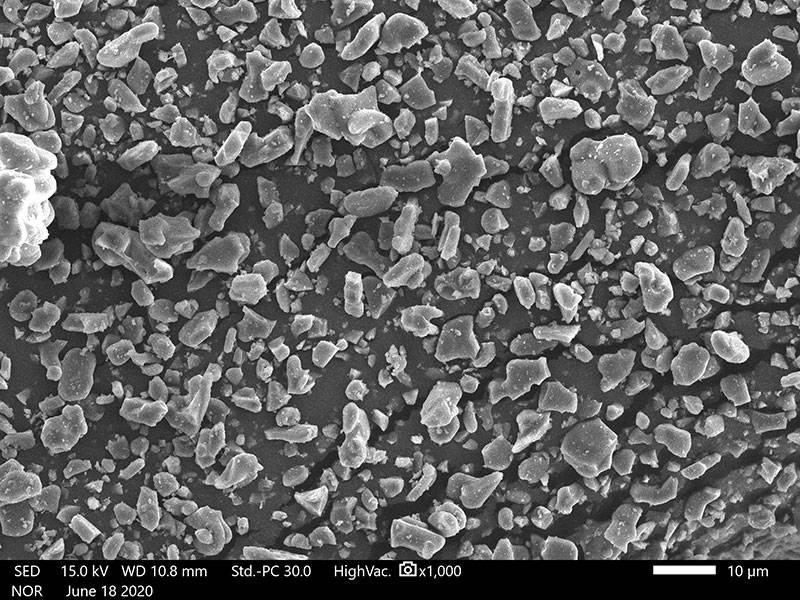

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment ,excellent talents and continuously strengthened technology forces for PriceList for Reactive Alpha Alumina Powder - Low-Sodium Calcined Alumina (HA) Series Coarse Powder – Yufa , The product will supply to all over the world, such as: Libya, Paraguay, Kuwait, we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

Write your message here and send it to us