OEM/ODM Manufacturer Alpha Alumina For Alumina Ball - Low Sodium Calcined Alumina (CA) Series for Ceramics – Yufa

OEM/ODM Manufacturer Alpha Alumina For Alumina Ball - Low Sodium Calcined Alumina (CA) Series for Ceramics – Yufa Detail:

Applications

| Model No. | Chemical Composition(%) | True Density | Apparent Density | Grain Size D50 | +325 Mesh | Original Crystal D50 | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

<% | D50(μm) | |||

| CA1A | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.97 | >0.95 | ~70 | 5.0-6.0 | 1. High temperature calcination 2. Low sodium 3. Large crystal 4. High conversion rate 5. Stable shrinkage. Good fluidity 6. High insulation performance 7. High mechanical strength |

1. High-performance ceramics, such as vacuum tubes 2. Especially suitable for hot -pressing casting process |

|

| CA1D | 99.5 | 0.05 | 0.03 | 0.08 | 0.1 | 3.95 | >0.90 | 3.0-4.0 | 1. Low sodium 2. Moderate crystal size 3. Good particle size distribution 4. Small shrinkage and stability |

1. Spark plugs 2. Vacuum tubes 3. Wear-resistant ceramics, etc. 4. More suitable for static pressure, dry-pressing and other forming processes |

||

| CA1 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.95 | >0.90 | 3.0-3.8 | 1. Static kiln calcination 2. Low sodium 3. Moderate crystal size 4. Good particle size distribution 5. High porcelain density |

1. Mainly used in electronic ceramics 2. Especially suitable for Hot die casting process |

||

| CA2 | 99.5 | 0.08 | 0.03 | 0.08 | 0.1 | 3.96 | >0.90 | 2.8-3.8 | 1. Low sodium 2. Strict crystal size control 3. Good fluidity 4. Stable shrinkage |

1. Electronic ceramics, structural ceramics 2. Especially suitable for Hot die casting process |

||

| CA2G | 0.15 | >0.90 | 3.0-3.5 | < 3.0 | 1. CA2 full grinding 2. Particle size control stability 3. Low sodium 4. Shrinkage stability |

1. Electronic ceramics 2. Structural ceramics, more suitable for making ceramic rollers |

||||||

| CA3 | 99.5 | 0.05 | 0.03 | 0.04 | 0.1 | 3.96 | >0.85 | ~70 | 2.0-2.6 | 1. Strict control of firing temperature 2. Small crystal size 3. Good particle distribution 4. Pretty-low sodium |

Suitable for electronic ceramics, such as IC substrates | |

| CA3G | 0.1 | 2.4-2.9 | <1.0 | Fully grinding of CA3 | ||||||||

| CA4 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.93 | >0.90 | ~70 | 1.0-1.8 | 1. Good activity 2. Low sodium 3. High density after firing 4. Stable shrinkage 5. High mechanical strength |

1. Structural ceramics 2. Electronic ceramics 3. 99 alumina ceramic granulation powder material 4. Suitable for extrusion molding process as well |

|

| CA4G | 0.1 | >0.60 | 1.5-2.2 | <1.0 | Fully grinding of CA4 | |||||||

| CA5 | 99.5 | 0.05 | 0.02 | 0.05 | 0.1 | 3.92 | ~70 | <1.0 | 1. Small & unifrom crystal size 2. Good activity |

99 alumina ceramic hot die casting process, etc | ||

| CA5G | 1-1.3 | <1.0 | 1. Small & unifrom crystal size 2. Good activity 3. Fully grinding 4. Narrow particle size distribution |

Ceramic filter,etc | ||||||||

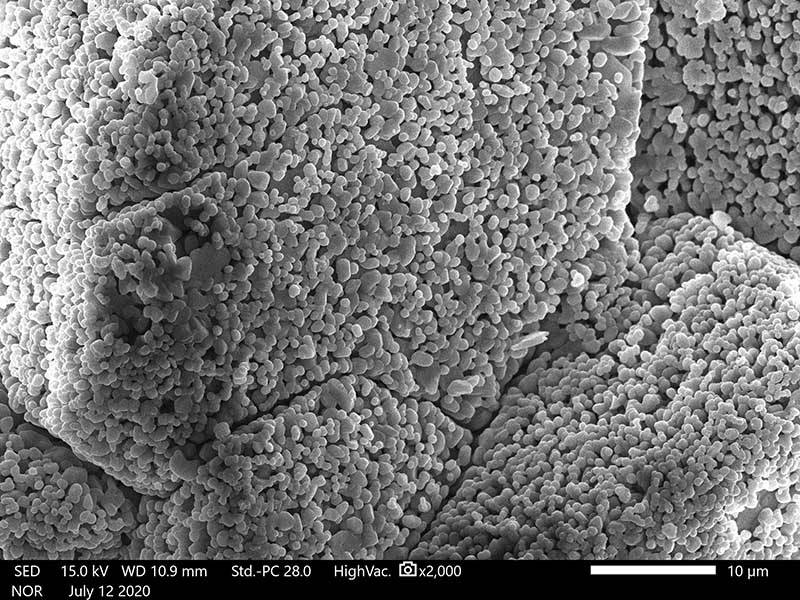

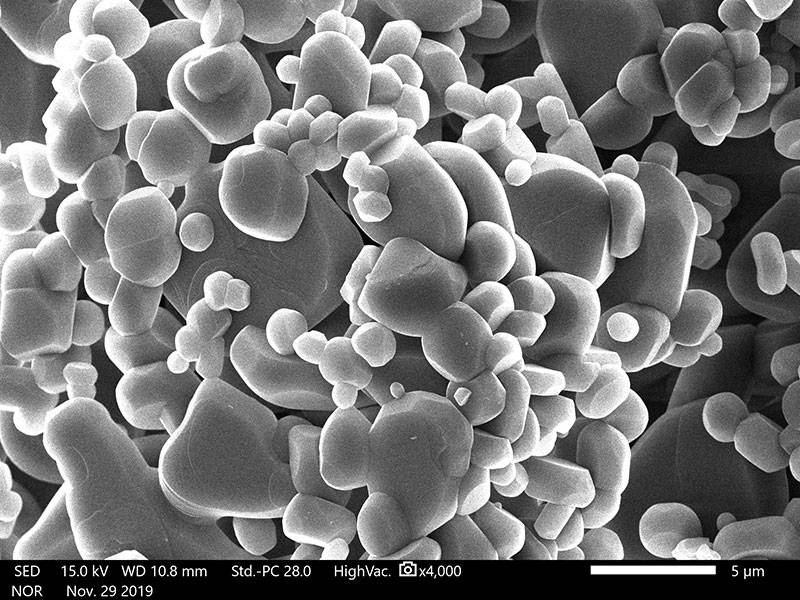

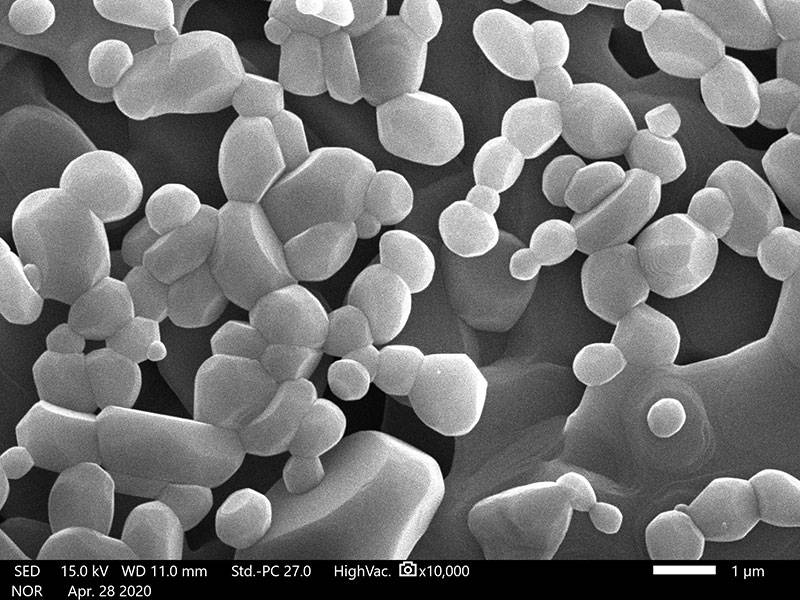

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for OEM/ODM Manufacturer Alpha Alumina For Alumina Ball - Low Sodium Calcined Alumina (CA) Series for Ceramics – Yufa , The product will supply to all over the world, such as: Angola, Melbourne, Ireland, We have sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

Write your message here and send it to us