OEM Supply Ceramic Granulation Powder - Calcined Alumina (RA) Series for Refractory Materials – Yufa

OEM Supply Ceramic Granulation Powder - Calcined Alumina (RA) Series for Refractory Materials – Yufa Detail:

Specification

| Model No. | Chemical Composition(%) | True Density | Apparent Density | Grain Size | +325 Mesh | Original Crystal | Water Absorption | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

<% | D50(μm) | % | |||

| RA1G | 99.5 | 0.15 | 0.04 | 0.10 | 0.15 | 3.92 | 0.7 | 1.5-2.2 | 1 | ~1.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

Used to produce various high-end refractory materials | |

| RA2GL | 99.5 | 0.15 | 0.04 | 0.10 | 0.15 | 3.94 | 0.7 | 2.3-2.7 | 1 | ~2.3 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

||

| RA2G | 99.5 | 0.15 | 0.05 | 0.15 | 0.1 | 3.95 | 0.85 | 3.0-3.6 | 2 | 2.5-3.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Reasonable particle size distribution 5. Certain activity |

||

| RA3GD | 99.5 | 0.08 | 0.04 | 0.10 | 0.1 | 3.95 | 0.83 | 4.0-5.0 | 2 | 4.0-4.5 | 1. Grinding, low sodium 2. High calcination temperature 3. Moderate primary crystal size 4. Good fluidity 5. Large bulk density |

||

| RA3G | 99.5 | 0.15 | 0.05 | 0.25 | 0.1 | 3.93 | 0.83 | 4.0-5.0 | 3 | 4.0-4.5 | T18-22 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Moderate primary crystal size 5. Good fluidity 6. Large bulk density |

|

| RA5G | 99.5 | 0.15 | 0.05 | 0.25 | 0.1 | 3.93 | 0.85 | 5.6-6.6 | 3 | 5.0-6.0 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Large primary crystal size 5. Good fluidity 6. Large bulk density |

||

Applications

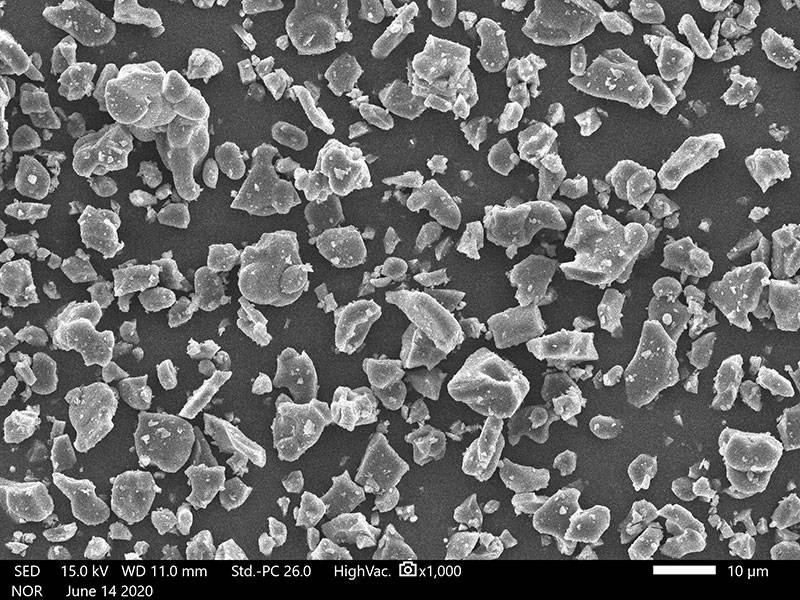

Product detail pictures:

Related Product Guide:

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for OEM Supply Ceramic Granulation Powder - Calcined Alumina (RA) Series for Refractory Materials – Yufa , The product will supply to all over the world, such as: Croatia, Swedish, Honduras, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

Write your message here and send it to us