OEM Manufacturer Ceramic Insulators Powder - Calcined Alumina (RA) Series for Refractory Materials – Yufa

OEM Manufacturer Ceramic Insulators Powder - Calcined Alumina (RA) Series for Refractory Materials – Yufa Detail:

Specification

| Model No. | Chemical Composition(%) | True Density | Apparent Density | Grain Size | +325 Mesh | Original Crystal | Water Absorption | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

<% | D50(μm) | % | |||

| RA1G | 99.5 | 0.15 | 0.04 | 0.10 | 0.15 | 3.92 | 0.7 | 1.5-2.2 | 1 | ~1.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

Used to produce various high-end refractory materials | |

| RA2GL | 99.5 | 0.15 | 0.04 | 0.10 | 0.15 | 3.94 | 0.7 | 2.3-2.7 | 1 | ~2.3 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

||

| RA2G | 99.5 | 0.15 | 0.05 | 0.15 | 0.1 | 3.95 | 0.85 | 3.0-3.6 | 2 | 2.5-3.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Reasonable particle size distribution 5. Certain activity |

||

| RA3GD | 99.5 | 0.08 | 0.04 | 0.10 | 0.1 | 3.95 | 0.83 | 4.0-5.0 | 2 | 4.0-4.5 | 1. Grinding, low sodium 2. High calcination temperature 3. Moderate primary crystal size 4. Good fluidity 5. Large bulk density |

||

| RA3G | 99.5 | 0.15 | 0.05 | 0.25 | 0.1 | 3.93 | 0.83 | 4.0-5.0 | 3 | 4.0-4.5 | T18-22 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Moderate primary crystal size 5. Good fluidity 6. Large bulk density |

|

| RA5G | 99.5 | 0.15 | 0.05 | 0.25 | 0.1 | 3.93 | 0.85 | 5.6-6.6 | 3 | 5.0-6.0 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Large primary crystal size 5. Good fluidity 6. Large bulk density |

||

Applications

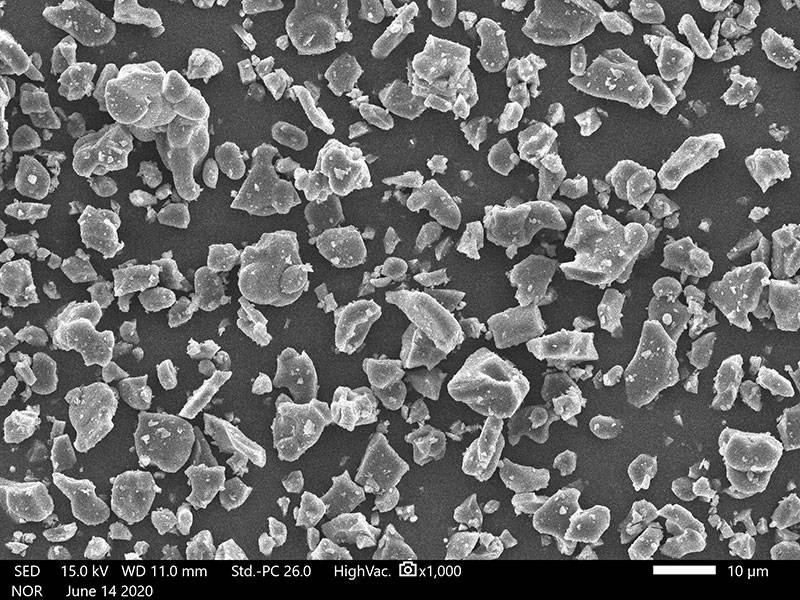

Product detail pictures:

Related Product Guide:

Our firm sticks on the theory of "Quality will be the life in the enterprise, and status could be the soul of it" for OEM Manufacturer Ceramic Insulators Powder - Calcined Alumina (RA) Series for Refractory Materials – Yufa , The product will supply to all over the world, such as: Portugal, South Korea, Mecca, We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.

Write your message here and send it to us