OEM Manufacturer Ceramic Insulators Powder - Calcined Alumina (FA) Series for Heat Conduction – Yufa

OEM Manufacturer Ceramic Insulators Powder - Calcined Alumina (FA) Series for Heat Conduction – Yufa Detail:

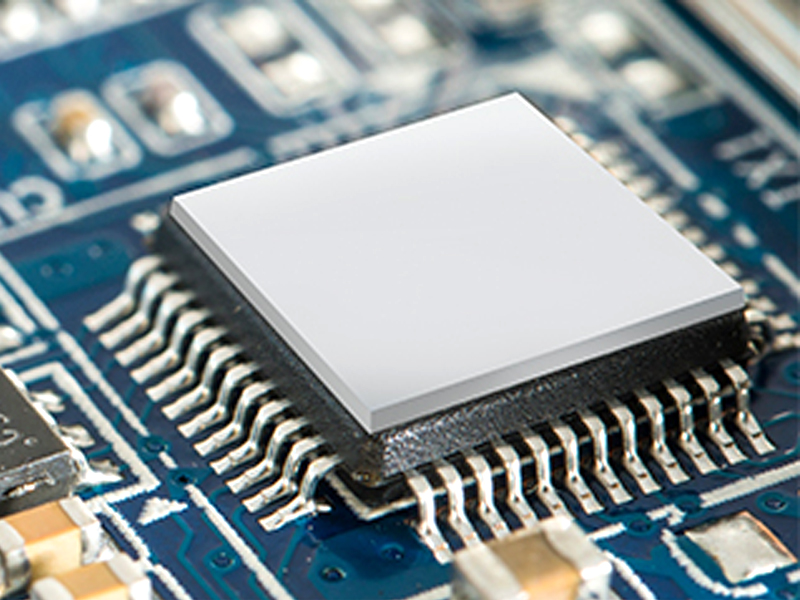

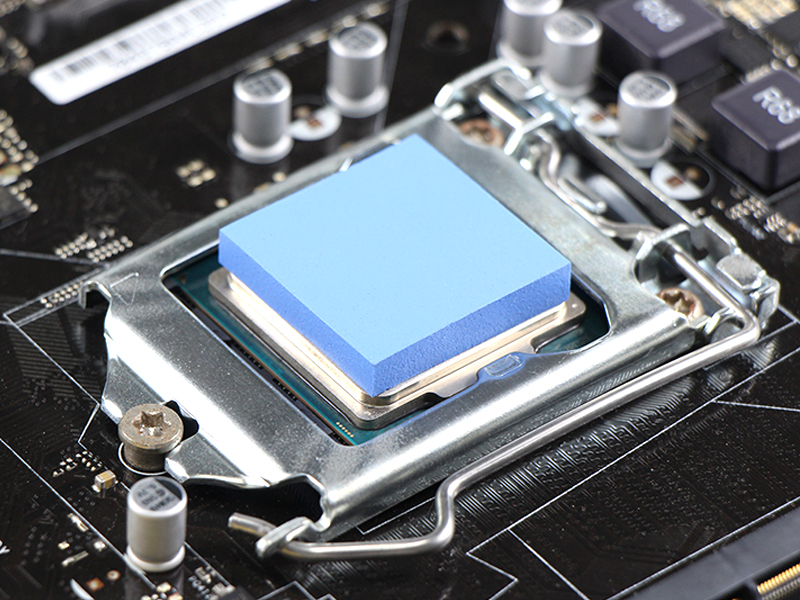

Applications

| Chemical Composition (%) | Ture Density | Apparent Density | Grain Size | Original Crystal | Oil Absorption Rate | Conversion Rate | +325 | Residual Boron | Features | Recommended Applications | |||||

| Model No. | Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

D50 (μm) |

ml | ≥% | <% | <% | ||

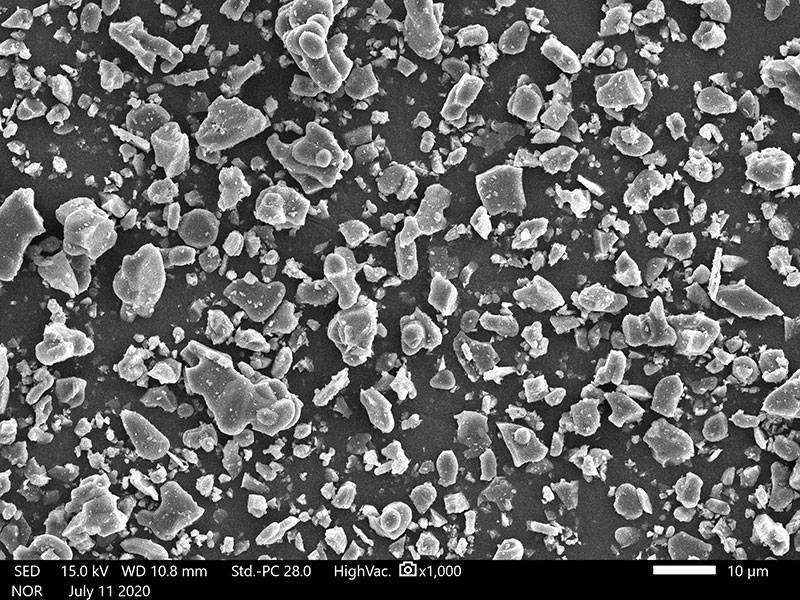

| FA3 | 99.5 | 0.1 | 0.03 | 0.08 | 0.1 | 3.96 | >0.85 | ~2.8 | 2.1-2.7 | <17 | ≥95 | 0.5 | / | 1. High temperature calcination 2. Deep grinding & Good flowability 3. Reasonable particle size distribution 4. Good thermo conductivity |

1. It can be used to thermal conductive materials 2. It suitable for ceramic coatings etc. |

| FA4 | 99.5 | 0.05 | 0.03 | 0.08 | 0.1 | 3.96 | >0.85 | ~4 | 3.6-4.5 | 13-15 | ≥95 | 0.5 | 0.02 | 1. High temperture clacination 2. Deep grinding 3. Reasonable grain size & crystal shape distribution 4. Good flowability & Good thermo conductivity |

|

| FA5 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~6 | 5.5-6 | ≤14 | ≥95 | 0.5 | 0.1 | 1. High temperature calcination 2. Deep grinding 3. Larger crystal paticle 4. Reasonable paricle distribution 5. High apparent density 6. Good flowability & good themo conductivity |

|

| FA10 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~10 | 8-10 | / | ≥95 | 1 | 0.1 | 1. Large crystal particle 2. Reasonable particle size distribution 3. High apparent density 4. Excellent flowability 5. Excellent thermo conductivity |

|

| FA15 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~13 | 10-13 | / | ≥95 | 1 | 0.1 | 1. Special production process 2. Large crystal particle 3. Good flowability 4. Good thermoconductivity |

|

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our enterprise with the long-term to build with each other with consumers for mutual reciprocity and mutual advantage for OEM Manufacturer Ceramic Insulators Powder - Calcined Alumina (FA) Series for Heat Conduction – Yufa , The product will supply to all over the world, such as: Irish, Provence, Guyana, we are sincerely hope to establish one good long term business relationship with your esteemed company thought this opportunity, based on equal, mutual beneficial and win win business from now till the future.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.

Write your message here and send it to us