OEM manufacturer Ceramic Igniter Part - Calcined Alumina (RA) Series for Refractory Materials – Yufa

OEM manufacturer Ceramic Igniter Part - Calcined Alumina (RA) Series for Refractory Materials – Yufa Detail:

Applications

| Model No. | Chemical Composition(%) | True density | Apparent density | Grain size | +325 mesh | Original Crystal | Water Absorption | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

d50 (μm) |

<% | d50(μm) | % | |||

| RA1G | 99.5 | 0.15 | 0.04 | 0.10 | 0.15 | 3.92 | 0.7 | 1.5-2.2 | 1 | ~1.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

Used to produce various high-end refractory materials | |

| RA2GL | 99.5 | 0.15 | 0.04 | 0.10 | 0.15 | 3.94 | 0.7 | 2.3-2.7 | 1 | ~2.3 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

||

| RA2G | 99.5 | 0.15 | 0.05 | 0.15 | 0.1 | 3.95 | 0.85 | 3.0-3.6 | 2 | 2.5-3.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Reasonable particle size distribution 5. Certain activity |

||

| RA3GD | 99.5 | 0.08 | 0.04 | 0.10 | 0.1 | 3.95 | 0.83 | 4.0-5.0 | 2 | 4.0-4.5 | 1. Grinding, low sodium 2. High calcination temperature 3. Moderate primary crystal size 4. Good fluidity 5. Large bulk density |

||

| RA3G | 99.5 | 0.15 | 0.05 | 0.25 | 0.1 | 3.93 | 0.83 | 4.0-5.0 | 3 | 4.0-4.5 | T18-22 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Moderate primary crystal size 5. Good fluidity 6. Large bulk density |

|

| RA5G | 99.5 | 0.15 | 0.05 | 0.25 | 0.1 | 3.93 | 0.85 | 5.6-6.6 | 3 | 5.0-6.0 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Large primary crystal size 5. Good fluidity 6. Large bulk density |

||

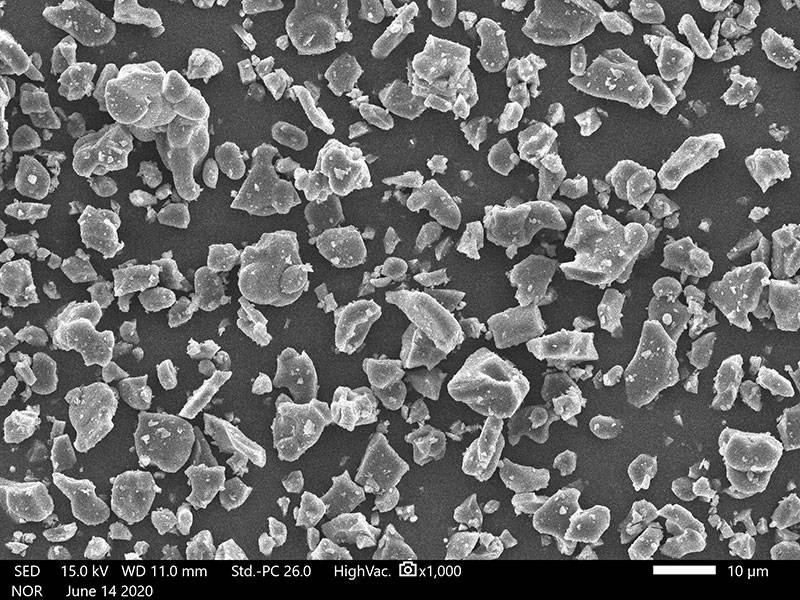

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for OEM manufacturer Ceramic Igniter Part - Calcined Alumina (RA) Series for Refractory Materials – Yufa , The product will supply to all over the world, such as: United Kingdom, Holland, Mauritius, For anyone who is keen on any of our goods right after you view our product list, please really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our products by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.

Write your message here and send it to us