OEM Factory for Ceramic Insulators - Low-Sodium Calcined Alumina (HA) Series Coarse Powder – Yufa

OEM Factory for Ceramic Insulators - Low-Sodium Calcined Alumina (HA) Series Coarse Powder – Yufa Detail:

| Model No. | Chemical Composition (%) | True Density | Apparent Density | Original Crystal | Conversion Rate | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

≥% | |||

| HA5 | 99.5 | 0.05 | 0.02 | 0.12 | 0.1 | 3.95 | 0.9 | 6.5-8.0 | 95 | 1. Unground & Low sodiume 2. Near-spherical crystal 3. Large crystal & Fully developed 4. Less shrinkage & Large output 5. Good quality stability |

1. Suitable for high-performance ceramics 2. Suitable for rough polishing 3. Suitable for refractory materials 4. Suitable for thermal conducting fillers 5. Suitable for wear-resistant coating industries |

| HA4 | 99.5 | 0.05 | 0.02 | 0.10 | 0.1 | 3.95 | 0.9 | 5.5-6.5 | |||

| HA3 | 99.5 | 0.05 | 0.02 | 0.12 | 0.1 | 3.95 | 0.9 | 4.5-5.6 | |||

| HA2 | 99.5 | 0.05 | 0.02 | 0.15 | 0.1 | 3.93 | 0.9 | 3.0-4.0 | 93 | 1. Unground, medium sodium 2. Near-spherical crystal 3. Crystal range of 2-3 μm 4. Good sinterability & Large output 5. Good quality stability. |

Suitable for ceramics and refractory industries. |

| HA1 | 99.7 | 0.05 | 0.02 | 0.01 | 0.1 | 3.93 | 0.9 | ~2 | 93 | 1. Extremely low impurities 2. Na2O≤ 0.01% 3. High conversion rate 4. Fine and uniform crystal |

1. Suitable for high-performance ceramics 2. Suitable for preparation of refractory powder 3. Suitable for wear-resistance coatings industries, etc. |

| HA2X | 99.5 | 0.10 | 0.02 | 0.08 | 0.1 | 3.95 | 0.9 | ~3 | 95 | 1. Easy to grind 2. Extremely low impurities 3. Good crystal sphericity 4. Narrow cystal distribution 5. Less shrinkage & Large output 6. Good quality stability |

1. Suitable for high-performance ceramics 2. Suitable for LCD glass, refractory materials 3. Suitable for thermally conductive fillers 4. Suitable for medium polishing materials industries, etc. |

| HA1X | 99.5 | 0.12 | 0.02 | 0.10 | 0.1 | 3.93 | 0.9 | ~2.3 | 93 | 1. Easy to grind & Low sodium 2. Good sphericity 3. Narrow cystal distribution 4. Small crystal & Good flowability 5. Large output & Good quality stability |

1. Suitable for the production of high-performance ceramics and refractory fine powder 2. It can be used in alumina ball |

| HA0X | 99.5 | 0.08 | 0.02 | 0.10 | 0.1 | 3.9 | 0.9 | ~1 | 92 | 1. Small crystal 2. Low impurities. |

1. Suitable for the production of high-performance ceramics and refractory powder preparation 2. It can used to preparation of wear-resistant coatings industries, etc 3. It can be used in alumina ball |

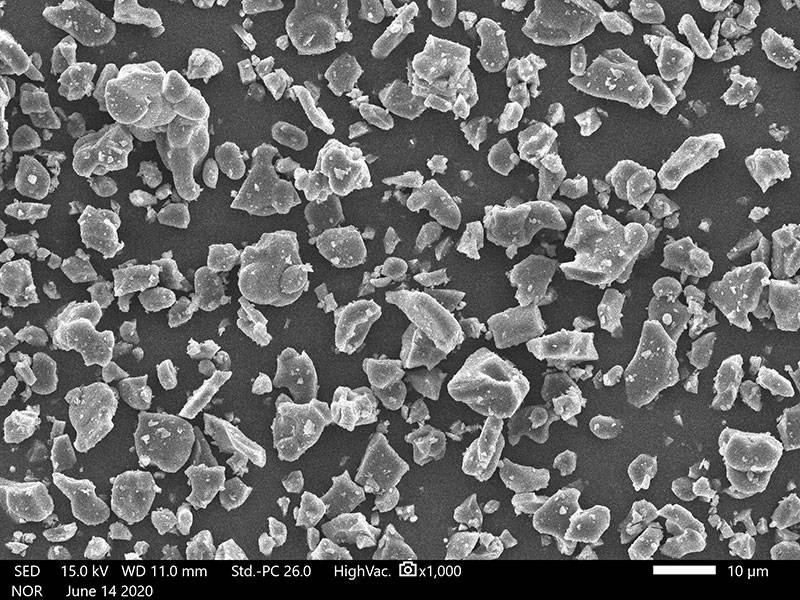

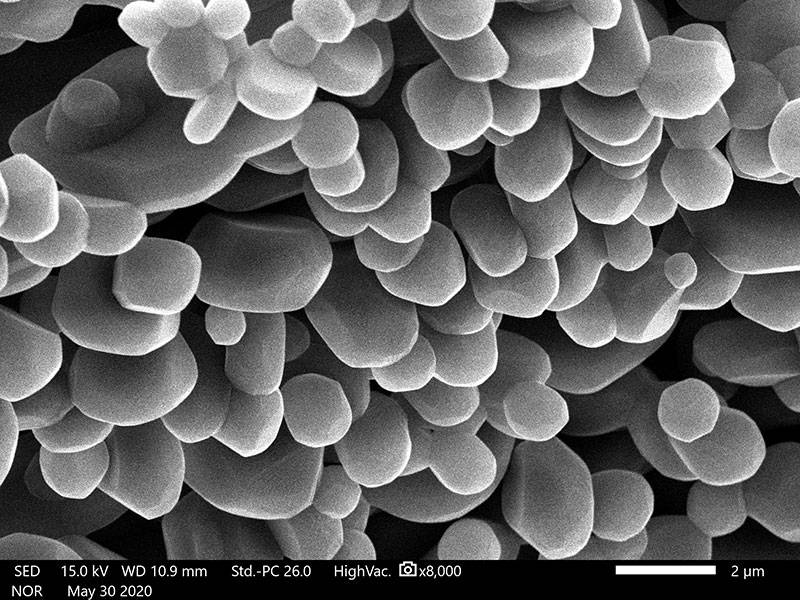

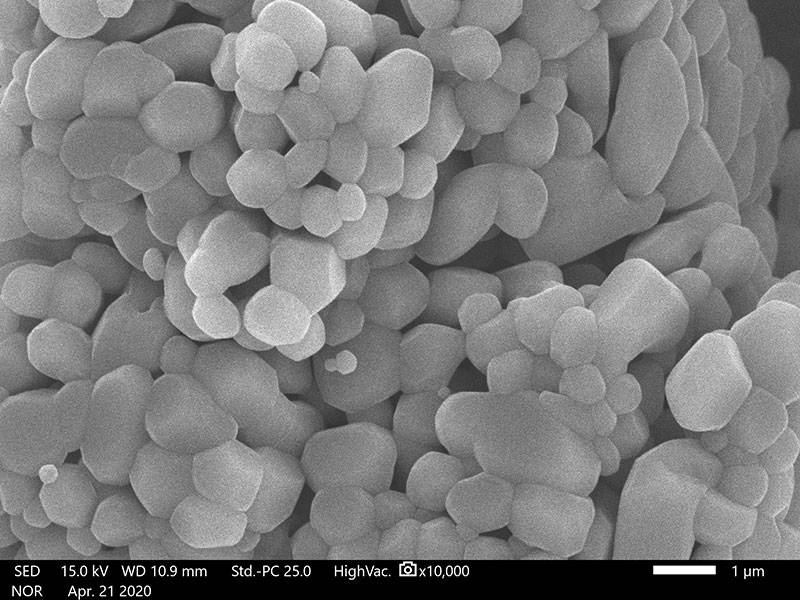

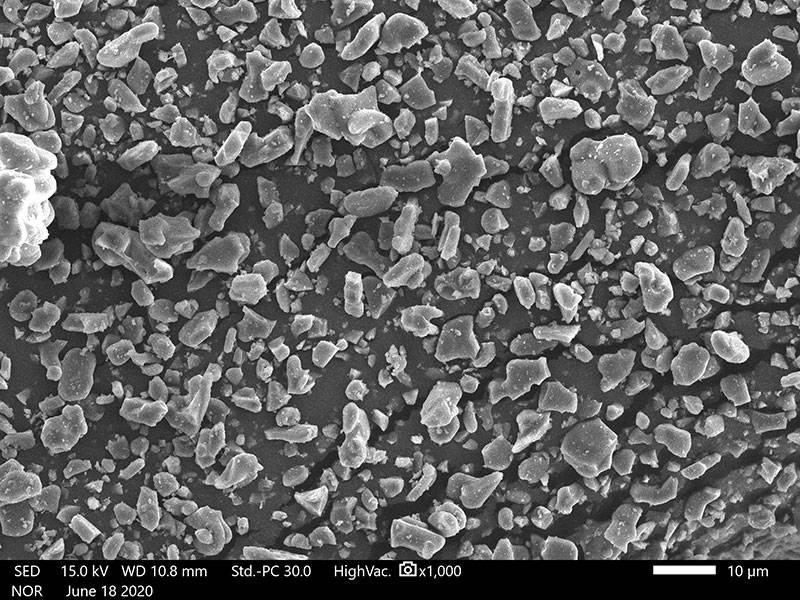

Product detail pictures:

Related Product Guide:

To regularly increase the management program by virtue from the rule of "sincerely, good religion and high quality are the base of enterprise development", we greatly absorb the essence of linked products internationally, and constantly produce new goods to satisfy the calls for of shoppers for OEM Factory for Ceramic Insulators - Low-Sodium Calcined Alumina (HA) Series Coarse Powder – Yufa , The product will supply to all over the world, such as: Mecca, Japan, Bandung, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

Write your message here and send it to us