OEM Factory for Ceramic Insulators - Calcined Alumina (FA) Series for Heat Conduction – Yufa

OEM Factory for Ceramic Insulators - Calcined Alumina (FA) Series for Heat Conduction – Yufa Detail:

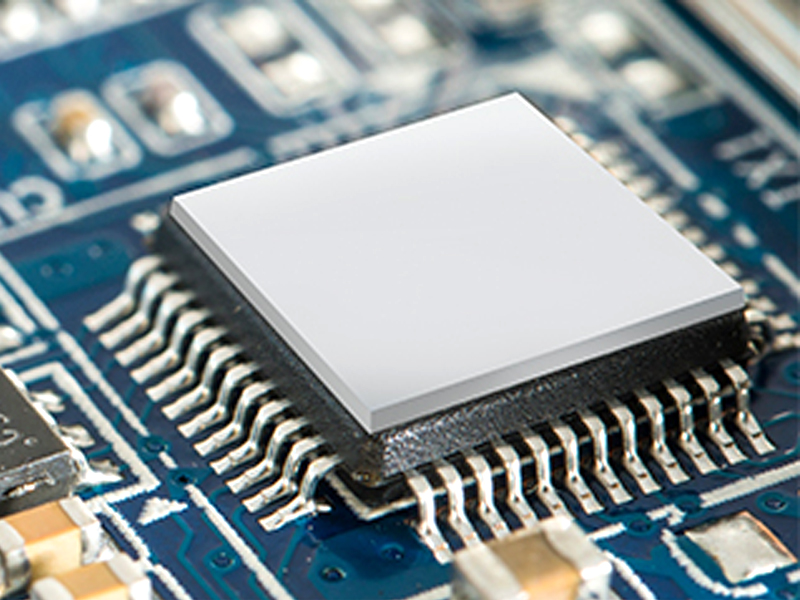

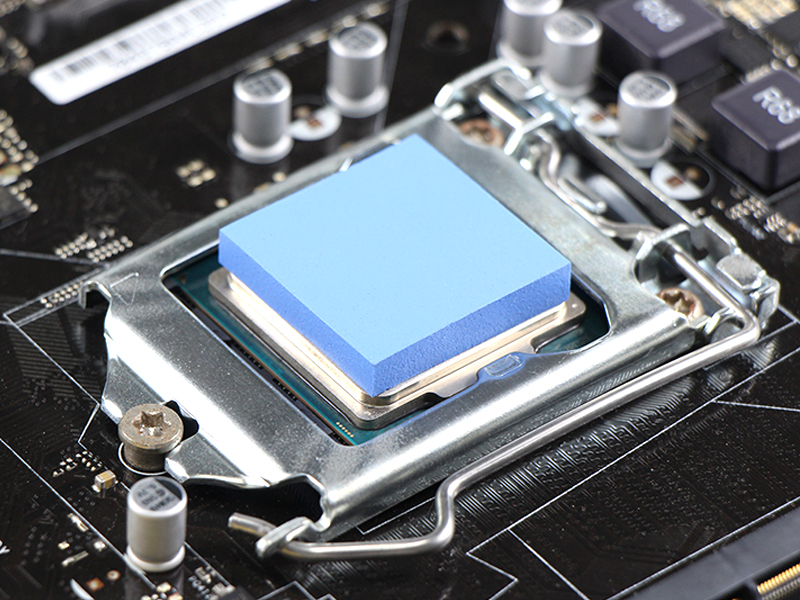

Applications

Specification

| Chemical Composition (%) | Ture Density | Apparent Density | Grain Size | Original Crystal | Oil Absorption Rate | Conversion Rate | +325 | Residual Boron | Features | Recommended Applications | |||||

| Model No. | Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

D50 (μm) |

ml | ≥% | <% | <% | ||

| FA3 | 99.5 | 0.1 | 0.03 | 0.08 | 0.1 | 3.96 | >0.85 | ~2.8 | 2.1-2.7 | <17 | ≥95 | 0.5 | / | 1. High temperature calcination 2. Deep grinding & Good flowability 3. Reasonable particle size distribution 4. Good thermo conductivity |

1. It can be used to thermal conductive materials 2. It suitable for ceramic coatings etc. |

| FA4 | 99.5 | 0.05 | 0.03 | 0.08 | 0.1 | 3.96 | >0.85 | ~4 | 3.6-4.5 | 13-15 | ≥95 | 0.5 | 0.02 | 1. High temperture clacination 2. Deep grinding 3. Reasonable grain size & crystal shape distribution 4. Good flowability & Good thermo conductivity |

|

| FA5 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~6 | 5.5-6 | ≤14 | ≥95 | 0.5 | 0.1 | 1. High temperature calcination 2. Deep grinding 3. Larger crystal paticle 4. Reasonable paricle distribution 5. High apparent density 6. Good flowability & good themo conductivity |

|

| FA10 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~10 | 8-10 | / | ≥95 | 1 | 0.1 | 1. Large crystal particle 2. Reasonable particle size distribution 3. High apparent density 4. Excellent flowability 5. Excellent thermo conductivity |

|

| FA15 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.96 | >0.85 | ~13 | 10-13 | / | ≥95 | 1 | 0.1 | 1. Special production process 2. Large crystal particle 3. Good flowability 4. Good thermoconductivity |

|

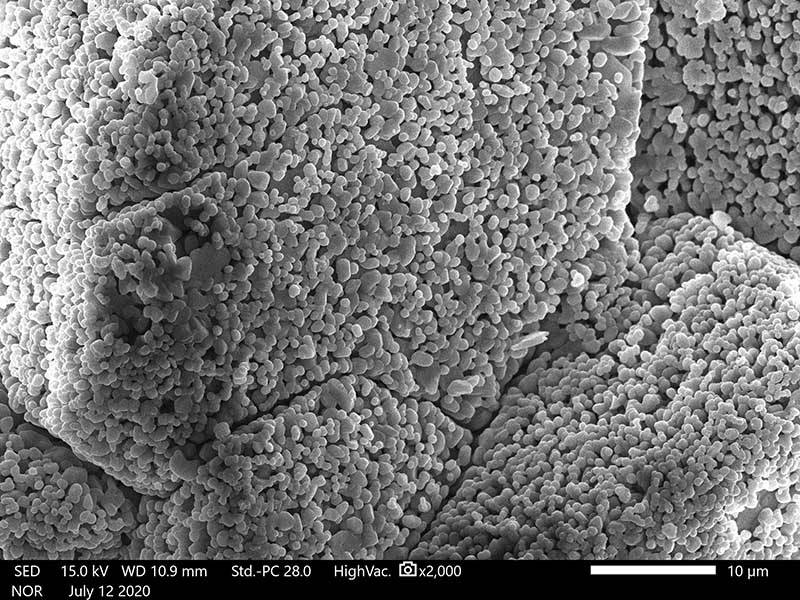

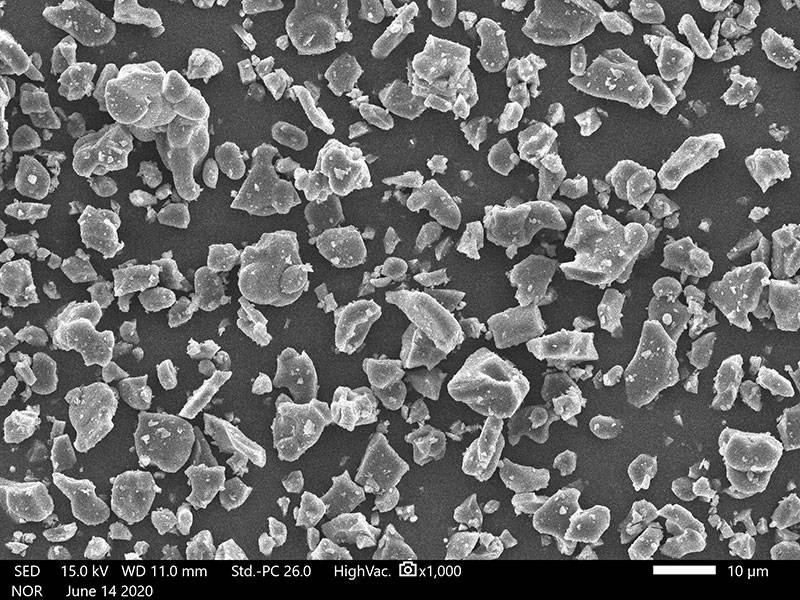

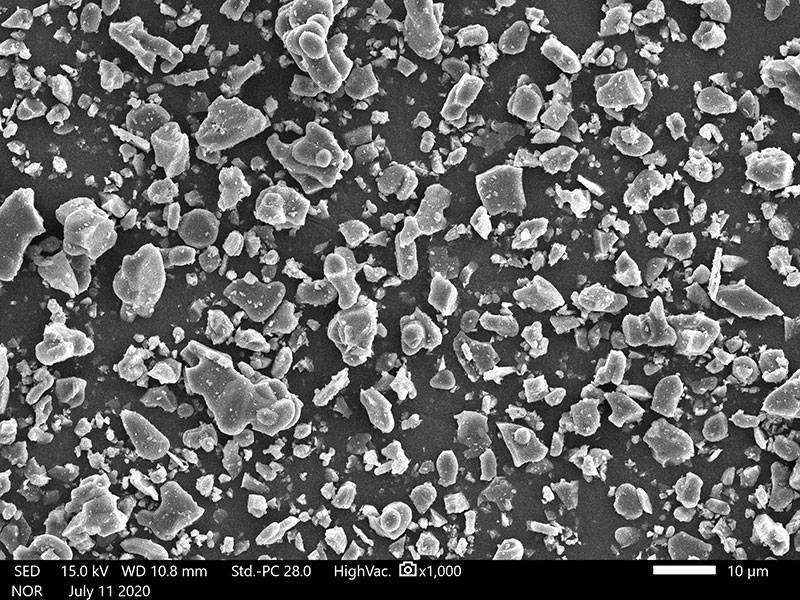

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for OEM Factory for Ceramic Insulators - Calcined Alumina (FA) Series for Heat Conduction – Yufa , The product will supply to all over the world, such as: Adelaide, Croatia, Kenya, To win customers' confidence, Best Source has set up a strong sales and after-sales team to deliver the best product and service. Best Source abides by the idea of "Grow with customer" and philosophy of "Customer-oriented" to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let's grow together!

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

Write your message here and send it to us