What role does Fused Alumina/Corundum play in refractory castables?

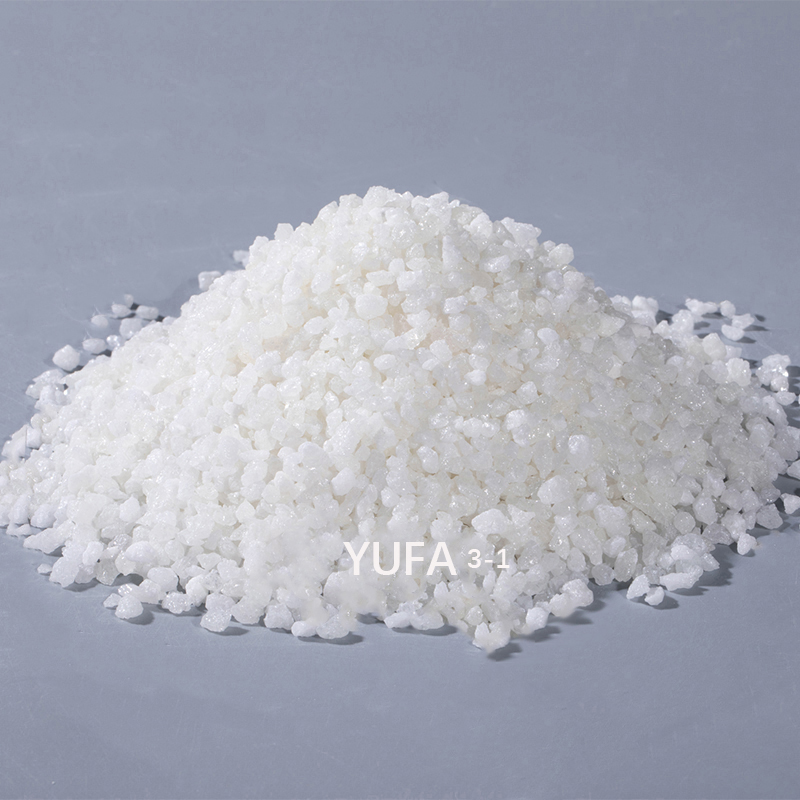

Hello everyone, today I will share with you the role of Fused Alumina/Corundum in refractory castables. Fused alumina/corundum is made from alumina raw materials that are continuously smelted at a high temperature of more than 2020 degrees Celsius in an electric furnace and then cooled and crushed.

The role of Fused alumina/corundum in castables includes the following aspects:

- Enhancing Refractoriness: Corundum (Al₂O₃) has a melting point of 2050°C, significantly improving the refractoriness of castables, allowing them to remain stable in high-temperature environments.

- Increasing Mechanical Strength: Corundum has high hardness and strength. When added to castables, it enhances their compressive strength, flexural strength, and impact resistance, thus increasing the durability of the castables.

- Improving Wear Resistance: Corundum has excellent wear resistance, enabling castables to withstand abrasion and erosion at high temperatures, thereby extending their service life.

- Enhancing Thermal Shock Stability: Corundum has a low thermal expansion coefficient and good thermal shock stability, effectively preventing cracks and spalling in castables during rapid temperature changes.

- Chemical Corrosion Resistance: Corundum is highly resistant to chemical corrosion from acids, alkalis, and other corrosive substances, making it suitable for various complex chemical environments.

- Reducing Porosity: Fine corundum powder fills the voids in castables, reducing porosity and improving the density and overall performance of the castables.

In summary, corundum plays a crucial role in enhancing the comprehensive performance of castables, allowing them to work stably under harsh conditions such as high temperatures, high pressure, and complex chemical environments.

Post time: Jul-17-2024