Introduction of Alumina Granulated Powder

Alumina granulated powder refers to the dry pressing or isostatic pressing of alumina ceramics production process, the ceramic slurry needs to be spray-dried to form a granular powder. Chinese name alumina granulation powder is suitable for rapid dry pressing, isostatic pressing, hot die casting, injection, spraying

Alumina Granulation powder requires good fluidity, certain strength of particles, not broken during transportation and feeding, certain particle gradation, close packing when feeding, certain bonding characteristics and Lubricating properties, particles should not stick to each other… etc. Granulation properties. Zhengzhou YUFA Fine Ceramics Technology Co., Ltd specializes in the production of alumina granulation powder. Through pressure spraying and centrifugal spraying, various particle gradations and high fluidity medium-solid alumina particles are formed.

Alumina granulated powder:

Common Types: Alumina Ceramic 80-99, Toughened Ceramic, wear-resistant Ceramic, steatite Ceramic, colored Ceramic. Wet process fine powder, porcelain powder.

Features: Ceramics formation at low temperature, high density, powder does not stick to the mold, no cracking, no pores in the Ceramics, good consistency of powder.

YUFA Types:

| YF-997 | YF-99D | YF-99T | YF-95D | YF-95S |

PS: Also customized services can be supported.

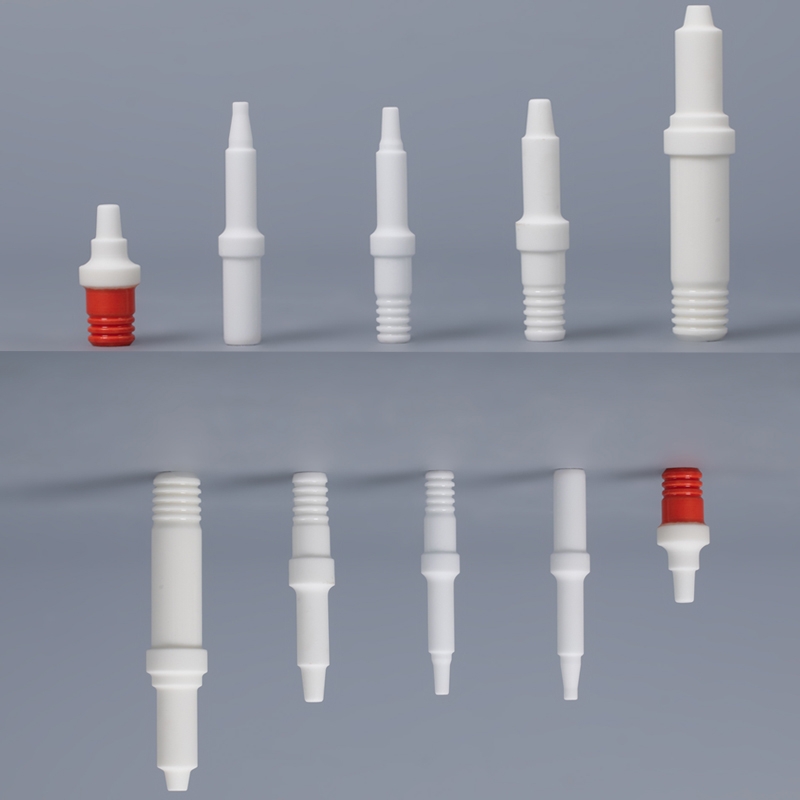

Application: For making 997/99/95/96 Alumina cramics.

Edit: Jenny Lee

Mob/Whatsapp: +86182364196217

Email: Jenny@yfml.com

Post time: Nov-17-2022