Fused dense corundum is a new type of high-performance alumina refractory material, which also has the characteristics of high-temperature resistance and wear resistance of alumina. It is a kind of high-purity refractory raw material that is formed by melting at a high temperature above 2300℃ in an electric arc furnace by using a special production process.

The main crystalline phase is α – Al2O3, with light gray in color, has high melting point, quite high bulk density, and very low porosity. It has excellent wear resistance, slag resistance, volume stability, scouring resistance, and thermal shock resistance at high temperatures. It is the best refractory raw material in corundum series refractory raw materials.

Fused dense corundum is one of the preferred raw materials for the production of high-performance amorphous and shaped refractories. It is widely used in industries like iron and steel, cement, ceramics, petrochemical, and other industries. It is an ideal raw material for making amorphous refractory materials such as blast furnace ditch castable, ladle castable, ramming material, and prefabricated parts, as well as various shaped products such as “three major parts of continuous casting” (The three major parts of continuous casting refer to functional refractory elements such as integral stopper, long nozzle (large ladle long nozzle), submerged nozzle (nozzle used in tundish), tundish nozzle and so on), breathable brick and nozzle seat brick. It is also an excellent material for making steel-making long nozzle, sliding plate, and various corundum bricks.

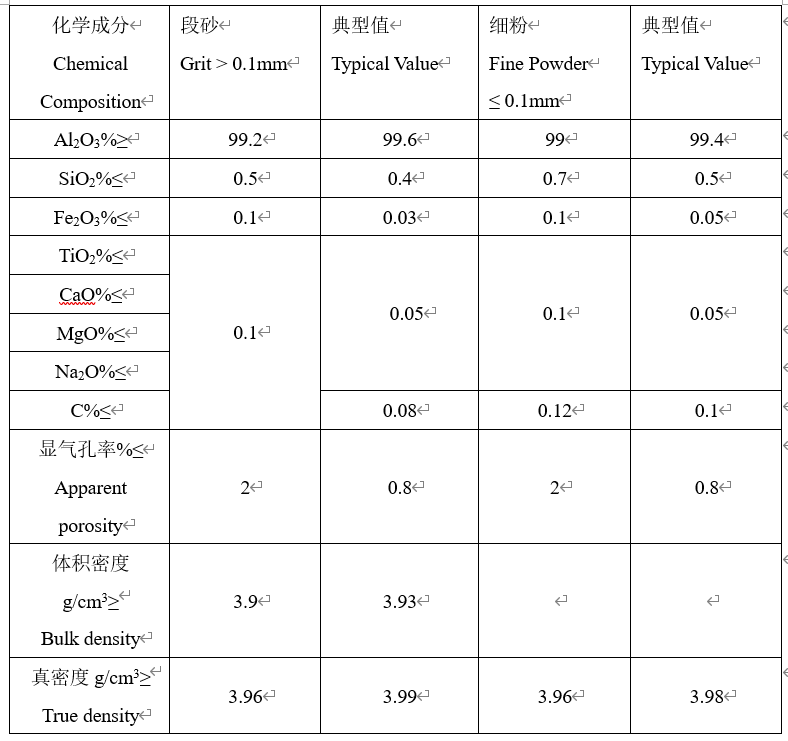

The following is the ingredient list of dense corundum products independently developed by Zhengzhou Yufa Abrasives Group.

Post time: Sep-23-2021