Manufactur standard Ceramic Powder Insulator - Calcined Alumina (RA) Series for Refractory Materials – Yufa

Manufactur standard Ceramic Powder Insulator - Calcined Alumina (RA) Series for Refractory Materials – Yufa Detail:

Specification

| Model No. | Chemical Composition(%) | True Density | Apparent Density | Grain Size | +325 Mesh | Original Crystal | Water Absorption | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

<% | D50(μm) | % | |||

| RA1G | 99.5 | 0.15 | 0.04 | 0.10 | 0.15 | 3.92 | 0.7 | 1.5-2.2 | 1 | ~1.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

Used to produce various high-end refractory materials | |

| RA2GL | 99.5 | 0.15 | 0.04 | 0.10 | 0.15 | 3.94 | 0.7 | 2.3-2.7 | 1 | ~2.3 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

||

| RA2G | 99.5 | 0.15 | 0.05 | 0.15 | 0.1 | 3.95 | 0.85 | 3.0-3.6 | 2 | 2.5-3.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Reasonable particle size distribution 5. Certain activity |

||

| RA3GD | 99.5 | 0.08 | 0.04 | 0.10 | 0.1 | 3.95 | 0.83 | 4.0-5.0 | 2 | 4.0-4.5 | 1. Grinding, low sodium 2. High calcination temperature 3. Moderate primary crystal size 4. Good fluidity 5. Large bulk density |

||

| RA3G | 99.5 | 0.15 | 0.05 | 0.25 | 0.1 | 3.93 | 0.83 | 4.0-5.0 | 3 | 4.0-4.5 | T18-22 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Moderate primary crystal size 5. Good fluidity 6. Large bulk density |

|

| RA5G | 99.5 | 0.15 | 0.05 | 0.25 | 0.1 | 3.93 | 0.85 | 5.6-6.6 | 3 | 5.0-6.0 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Large primary crystal size 5. Good fluidity 6. Large bulk density |

||

Applications

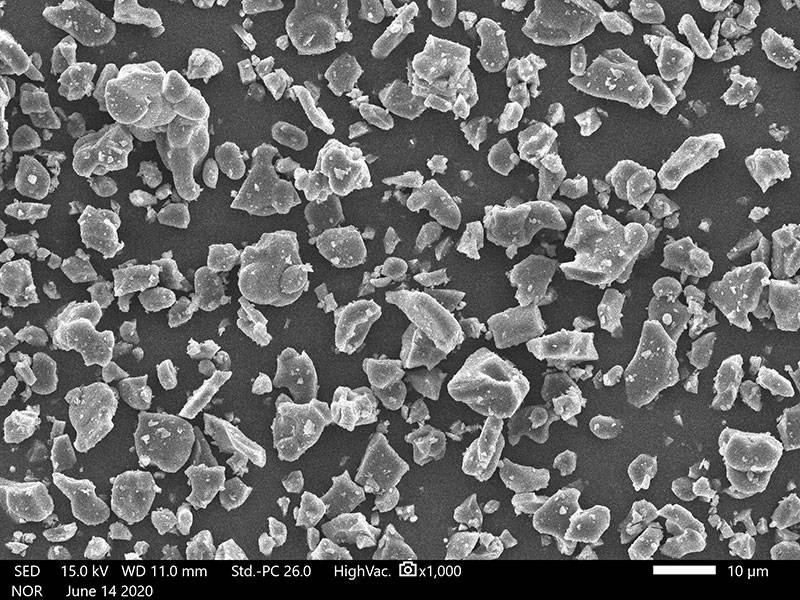

Product detail pictures:

Related Product Guide:

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for Manufactur standard Ceramic Powder Insulator - Calcined Alumina (RA) Series for Refractory Materials – Yufa , The product will supply to all over the world, such as: USA, Denmark, Johor, Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.

Write your message here and send it to us