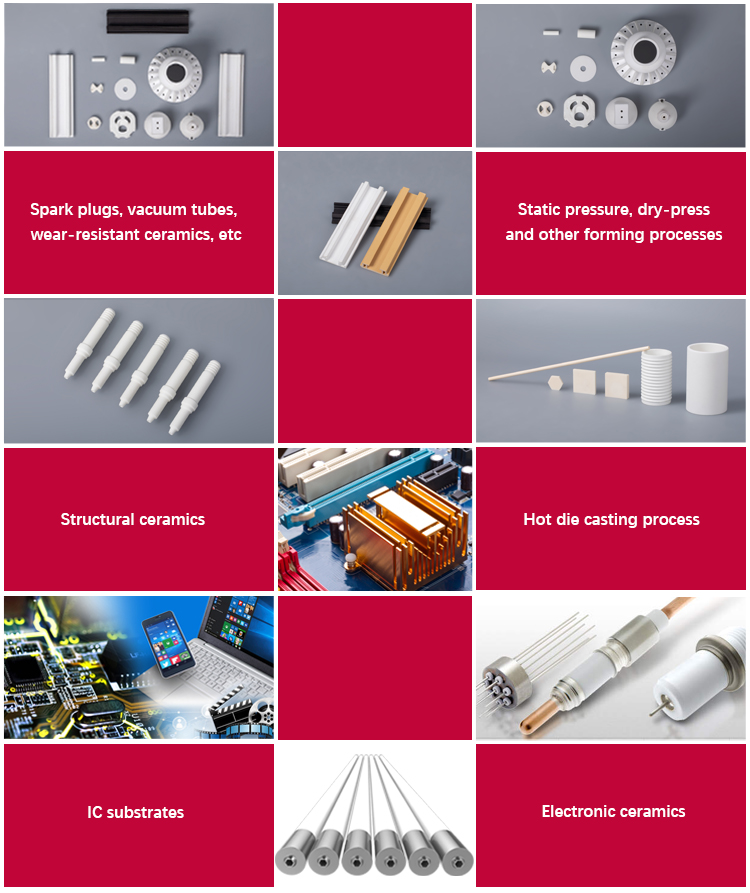

Low Sodium Calcined Alumina (CA) Series for Ceramics

Applications

Specification

| Model No. | Chemical Composition(%) | True Density | Apparent Density | Grain Size D50 | +325 Mesh | Original Crystal D50 | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

d50 (μm) |

<% | d50(μm) | |||

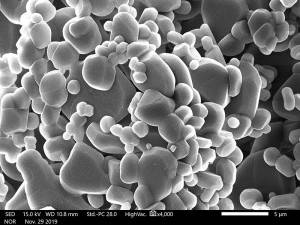

| CA1A | 99.7 | 0.05 | 0.02 | 0.08 | 0.1 | 3.97 | >0.95 | ~70 | \ | 5.0±0.3 | High temperature calcination, low sodium, large crystal, high conversion rate, stable shrinkage. Good fluidity, high insulation performance, high mechanical strength | High-performance ceramics, such as vacuum tubes. Especially suitable for hot -pressing casting process |

| CA1D | 99.7 | 0.05 | 0.02 | 0.06 | 0.1 | 3.95 | >0.90 | \ | 4.3-4.7 | Low sodium, moderate crystal size, good particle size distribution, small shrinkage and stability | Spark plugs, vacuum tubes, wear-resistant ceramics, etc. More suitable for static pressure, dry-press and other forming processes | |

| CA1 | 99.7 | 0.05 | 0.02 | 0.05 | 0.1 | 3.95 | >0.90 | \ | 4.2-4.8 | Static kiln calcination, low sodium, moderate crystal size, good particle size distribution, high porcelain density. | Mainly used in electronic ceramics. Especially suitable for Hot die casting process | |

| CA2D | 99.7 | 0.06 | 0.02 | 0.06 | 0.1 | 3.95 | >0.80 | \ | 3.0-3.5 | Low sodium/soda, No boron, Smaller crystals, Uniform particle size, Less shrinkage. | IC substrates, spark plugs, vacuum tubes, wear-resistant ceramics, etc. Suitable for Tap casting, Sliping, Isostatic pressing, Dry pressing and other molding processes. |

|

| CA2 | 99.7 | 0.08 | 0.02 | 0.04 | 0.1 | 3.96 | >0.90 | \ | 3.85-4.15 | Low sodium, strict crystal size control, good fluidity and stable shrinkage | Electronic ceramics, structural ceramics. Especially suitable for Hot die casting process. | |

| CA2G | 99.6 | 0.15 | 0.02 | >0.90 | 3.5-3.8 | < 3.0 | 3.4-3.6 | full grinding, particle size control stability, low sodium, shrinkage stability | Electronic ceramics, structural ceramics. More suitable for making ceramic rollers | |||

| CA3D | 99.7 | 0.06 | 0.02 | 0.06 | 0.1 | 3.95 | >0.80 | ~70 | \ | 2.5-3.0 | Low sodium, Boron-free, Small crystals, Uniform particle size, and Stable shrinkage. | IC substrates, spark plugs, wear-resistant ceramics, etc. Suitable for Tap casting, Sliping, Isostatic pressing, Dry pressing and other molding processes. |

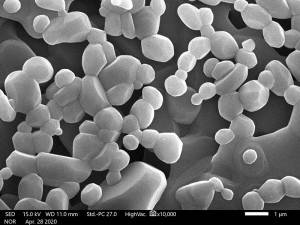

| CA3 | 99.7 | 0.05 | 0.02 | 0.04 | 0.1 | 3.96 | >0.85 | \ | 2.2-2.6 | Strict control of firing temperature, small crystal size, good particle distribution, pretty-low sodium. | Suitable for electronic ceramics, such as IC substrates | |

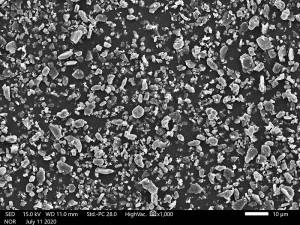

| CA3G | 0.1 | 2.3-2.7 | <1.0 | Fully grinding of CA3 | ||||||||

| CA4 | 99.7 | 0.05 | 0.02 | 0.06 | 0.1 | 3.93 | >0.90 | ~70 | \ | 1.0-1.8 | Good activity, low sodium, high density after firing, stable shrinkage, high mechanical strength | Structural ceramics, electronic ceramics. 99 porcelain granulation powder material, also suitable for extrusion molding process |

| CA4G | 0.1 | >0.60 | 1.5-2.2 | <1.0 | Fully grinding of CA4 | |||||||

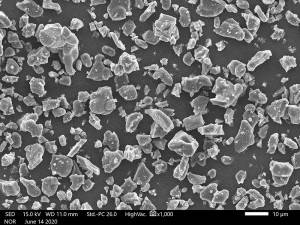

| CA5 | 99.7 | 0.05 | 0.02 | 0.05 | 0.1 | 3.92 | ~70 | \ | <1.0 | The crystals are small, with good activity and uniform crystal size. | 99 porcelain hot die casting process, etc | |

| CA5G | 1-1.3 | <1.0 | The crystals are small,have good activity, fully grinding, the crystal size is uniform, and the particle size distribution is narrow. | Ceramic filter,etc | ||||||||

| Model No. | Al2O3 (%)≥ | Chemical Composition(%)≤ | ≤Moisture content(%)≤ | Particle size characteristic value (μm) | BET (m2/g) | pH | ||||||

| Fe2O3 | K2O | Na2O | CaO | D10 | D50 | D90 | D99 | |||||

| CX-01 | 0.015 | 0.005 | 0.1 | 0.02 | 0.5 | 0.2 | 0.4-0.6 | 1.4 | 1.8 | 12~15 | 6~9 | |

| CX-02 | 99.7 | 0.02 | 0.005 | 0.08 | 0.02 | 0.3 | 0.6~0.8 | 1.5 | 1.9 | 10~13 | 6~9 | |

| CX-03 | 0.02 | 0.005 | 0.08 | 0.02 | 0.6 | 0.8~1.0 | 1.6 | 2 | 8~11 | 6~9 | ||

Write your message here and send it to us