High reputation White Corundum Abrasive - White Fused Alumina for Abrasives – Yufa

High reputation White Corundum Abrasive - White Fused Alumina for Abrasives – Yufa Detail:

PEFA F Grain & Micro Powder: Chemical Composition And Particle Size Composition Standard

Chemical Composition

|

Chemical Composition |

Na2O%≤ |

Al2O3%≥ |

SiO2%≤ |

Fe2O3%≤ |

Magnetic Object %≤ |

|

Common |

0.3 |

99.4 |

0.1 |

0.05 |

0.001 |

|

Micro Sodium |

0.06 |

99.7 |

0.1 |

0.03 |

0.001 |

F12 - F220 Particle Size Composition

| Grain Size Marking |

Ultra Coarse Grains |

Coarse Grains |

Medium Grains |

Mixed Grains |

Fine Grains |

|||

|

100% Pass The Following Sieves/Sieve Number |

Can not Pass The Following Sieves/Sieve Number |

Weight≤% |

The Sieve Can Not Pass/Sieve Number |

Weight ≥% |

The Sieve Can Not Pass/Sieve Number |

Weight ≥ % |

The largest quantity passing through following sieve≤3% |

|

|

F12 |

7 |

10 |

18 |

12 |

48 |

12 14 |

70 |

16 |

|

F14 |

8 |

12 |

18 |

14 |

48 |

14 16 |

70 |

18 |

|

F16 |

10 |

14 |

18 |

16 |

48 |

16 18 |

72 |

20 |

|

F20 |

12 |

16 |

18 |

18 |

48 |

18 20 |

72 |

25 |

|

F22 |

14 |

18 |

18 |

20 |

48 |

20 25 |

72 |

30 |

|

F24 |

16 |

20 |

22 |

25 |

48 |

25 30 |

68 |

35 |

|

F30 |

18 |

25 |

22 |

30 |

48 |

30 35 |

68 |

40 |

|

F36 |

20 |

30 |

22 |

35 |

48 |

35 40 |

68 |

45 |

|

F40 |

25 |

35 |

28 |

40 |

43 |

40 45 |

68 |

50 |

|

F46 |

30 |

40 |

28 |

45 |

43 |

45 50 |

68 |

60 |

|

F54 |

35 |

45 |

28 |

50 |

43 |

50 60 |

68 |

70 |

|

F60 |

40 |

50 |

28 |

60 |

43 |

60 70 |

68 |

80 |

|

F70 |

45 |

60 |

23 |

70 |

42 |

70 80 |

66 |

100 |

|

F80 |

50 |

70 |

23 |

80 |

42 |

80 100 |

66 |

120 |

|

F90 |

60 |

80 |

18 |

100 |

42 |

100 120 |

66 |

140 |

|

F100 |

70 |

100 |

18 |

120 |

42 |

120 140 |

66 |

200 |

|

F120 |

80 |

120 |

18 |

140 |

42 |

140 170 |

66 |

230 |

|

F150 |

100 |

140 |

13 |

170 200 |

45 |

170 200 230 |

70 |

270 |

|

F180 |

120 |

170 |

13 |

200 230 |

45 |

200 230 270 |

70 |

270 ≤ 10% |

|

F220 |

140 |

200 |

13 |

230 270 |

45 |

230 270 325 |

70 |

325 ≤ 10% |

F230 - F1200 Micro Powder (sediment tube particle size analyzer)

|

Grain Size |

Ds3 Max μm |

Medium grain size Ds50 Value μm |

Ds95 min μm |

|

F230 |

77 |

55.7 ± 3.0 |

38 |

|

F240 |

68 |

47.5 ± 2.0 |

32 |

|

F280 |

60 |

39.9 ± 1.5 |

25 |

|

F320 |

52 |

32.8 ± 1.5 |

19 |

|

F360 |

46 |

26.7 ± 1.5 |

14 |

|

F400 |

39 |

21.4 ± 1.0 |

10 |

|

F500 |

34 |

17.1 ± 1.0 |

7 |

|

F600 |

30 |

13.7 ± 1.0 |

4.6 |

|

F800 |

26 |

11.0 ± 1.0 |

3.5 |

|

F1000 |

23 |

9.1 ± 0.8 |

2.4 |

|

F1200 |

20 |

7.6 ± 0.5 |

2.4 (80%) |

F12 - F220 Physical Index Parameters

|

Grain Size |

Bulk Density g/m³ |

Magnetic substance content % |

Cleanliness≥ |

Whiteness% |

|

F12 |

0.0004 |

98.5 |

56.4 |

|

|

F14 |

0.0001 |

98.5 |

51.5 |

|

|

F16 |

0.0001 |

98.5 |

60.4 |

|

|

F20 |

1.78 – 1.85 |

0.0003 |

98.2 |

61.3 |

|

F22 |

0.0003 |

97.9 |

69.9 |

|

|

F24 |

1.78 – 1.85 |

0.0004 |

97.4 |

70.1 |

|

F30 |

1.77 – 1.82 |

0.0003 |

97.0 |

71.5 |

|

F36 |

1.74 – 1.81 |

0.0004 |

96.4 |

74.8 |

|

F40 |

1.73 – 1.80 |

0.0005 |

95.8 |

76.8 |

|

F46 |

1.71 – 1.83 |

0.0005 |

94.9 |

77.4 |

|

F54 |

1.68 – 1.78 |

0.0004 |

94.0 |

78.9 |

|

F60 |

1.67 – 1.77 |

0.0003 |

92.9 |

78.0 |

|

F70 |

1.59 – 1.72 |

0.0003 |

91.0 |

77.5 |

|

F80 |

1.57 – 1.72 |

0.0002 |

89.8 |

78.0 |

|

F90 |

0.0001 |

88.0 |

80.4 |

|

|

F100 |

1.57 – 1.68 |

0.0001 |

86.5 |

81.0 |

|

F120 |

1.57 – 1.64 |

0.0002 |

83.9 |

81.4 |

|

F150 |

1.53 -1.64 |

0.0002 |

80.8 |

78.8 |

|

F180 |

1.53 -1.64 |

0.0007 |

77.3 |

82.8 |

|

F220 |

0.0015 |

73.0 |

82.6 |

Note: Bulk density can be adjusted according to customer demand.

PEFA P Grain & Micro Powder: Chemical Composition And Particle Size Composition Standard

Chemical Composition

|

Chemical Composition |

Na2o%≤ |

Al2o3%≥ |

Sio2%≤ |

Fe2o3%≤ |

Magnetic object %≤ |

|

Common |

0.3 |

99.4 |

0.1 |

0.05 |

0.001 |

|

Micro Sodium |

0.06 |

99.7 |

0.1 |

0.03 |

0.001 |

P12 - P220 Particle Size Composition

|

Grain Size

|

Ultra Coarse Grains |

Coarse Grains |

Medium Grains |

Mixed Grains |

Fine Grains |

|||||||

|

100% pass Sieve 1 |

Can not pass Sieve 2 |

%≤ |

Can not pass Sieve 3 |

Cumulative 2+3% |

Can not pass the Sieve 4 |

Cumulative 2+3+4$ |

Can not pass Sieve 5

|

Cumulative 2+3+4+5≥% |

Can pass Sieve 5 |

%≤ |

||

|

P12 |

6 |

8 |

1 |

10 |

14 ± 4 |

12 |

61 ± 9 |

14 |

92 |

14 |

8 |

|

|

P16 |

8 |

12 |

3 |

14 |

26 ± 6 |

16 |

75 ± 9 |

18 |

96 |

18 |

4 |

|

|

P20 |

12 |

16 |

7 |

18 |

42 ± 8 |

20 |

86 ± 6 |

25 |

96 |

25 |

4 |

|

|

P24 |

14 |

18 |

1 |

20 |

14 ± 4 |

25 |

61 ± 9 |

30 |

92 |

30 |

8 |

|

|

P30 |

16 |

20 |

1 |

25 |

14 ± 4 |

30 |

61 ± 9 |

35 |

92 |

35 |

8 |

|

|

P36 |

18 |

25 |

1 |

30 |

14 ± 4 |

35 |

61 ± 9 |

40 |

92 |

40 |

8 |

|

|

P40 |

25 |

35 |

7 |

40 |

42 ± 8 |

45 |

86 ± 6 |

50 |

96 |

50 |

4 |

|

|

P50 |

30 |

40 |

3 |

45 |

26 ± 6 |

50 |

75 ± 9 |

60 |

96 |

60 |

4 |

|

|

P60 |

35 |

45 |

1 |

5 |

14 ± 4 |

60 |

61 ± 9 |

70 |

92 |

70 |

8 |

|

|

P80 |

45 |

60 |

3 |

70 |

26 ± 6 |

80 |

75 ± 9 |

100 |

96 |

100 |

4 |

|

|

P100 |

50 |

70 |

1 |

80 |

14 ± 4 |

100 |

61 ± 9 |

120 |

92 |

120 |

8 |

|

|

P120 |

70 |

100 |

7 |

120 |

42 ± 8 |

140 |

86 ± 6 |

170 |

96 |

170 |

4 |

|

|

P150 |

80 |

120 |

3 |

140 |

26 ± 6 |

170 |

75 ± 9 |

200 |

96 |

200 |

4 |

|

|

P180 |

100 |

140 |

2 |

170 |

15 ± 5 |

200 |

62 ± 12 |

230 |

90 |

200 |

10 |

|

|

P220 |

120 |

170 |

2 |

200 |

15 ± 5 |

230 |

62 ± 12 |

270 |

90 |

270 |

10 |

|

P240 - P2500 Micro Powder (sediment tube particle size analyzer)

|

Grain Size |

Ds0 max μm |

Ds3 Max μm |

Medium grain size Ds50 Value μm |

Ds95 Min μm |

|

P240 |

110 |

81.7 |

58.5 ± 2 |

44.5 |

|

P280 |

101 |

74.0 |

52.2 ± 2.0 |

39.2 |

|

P320 |

94 |

66.8 |

46.2 ± 1.5 |

34.2 |

|

P360 |

87 |

60.3 |

40.5 ± 1.5 |

29.6 |

|

P400 |

81 |

53.9 |

35.0 ± 1.5 |

25.2 |

|

P500 |

77 |

48.3 |

30.2 ± 1.5 |

21.5 |

|

P600 |

72 |

43.0 |

25.8 ± 1.0 |

18.0 |

|

P800 |

67 |

38.1 |

21.8 ± 1.0 |

15.1 |

|

P1000 |

63 |

33.7 |

18.3 ± 1.0 |

12.4 |

|

P1200 |

58 |

29.7 |

15.3 ± 1.0 |

10.2 |

|

P1500 |

58 |

25.8 |

12.6 ± 1.0 |

8.3 |

|

P2000 |

58 |

22.4 |

10.3 ± 0.8 |

6.7 |

|

P2500 |

58 |

19.3 |

8.4 ± 0.5 |

5.4 |

Grain Size and Micro Powder

PEFA F

F12, F24, F30, F36, F40, F46, F54, F60, F80, F100, F120, F150, F180, F220

F240, F280, F320, F360, F400, F500, F600, F800, F1000, F1200

PEFA P

P24, P30, P36, P40, P50, P60, P80, P100, P120, P150, P180, P220

P240, P280, P320, P360, P400, P500, P600, P800, P1000, P1200, P1500, P2000, P2500, P3000

JIS

JIS240, JIS280, JIS320, JIS360, JIS400, JIS500, JIS600, JIS700, JIS800, JIS1000, JIS1200, JIS1500, JIS2000, JIS2500, JIS3000, JIS4000, JIS6000, JIS8000

Other spec are available upon request. Low sodium, Micro sodium WFA are both available.

Product Advantages

1. Low sodium and micro sodium WFA can be provided. Na2O of our micro sodium WFA is less than 0.1%, can be double 0.

2. High cleanliness, strong adhesion, high hardness and strong cutting force, whiteness can be based on customer needs.

3. High bulk density and high transparent wear-resistance sands can be provided. The crystal is rounder than normal ball mill WFA.

4. Various specifications can be supported, and the bulk density can be adjusted according to customer’s demand.

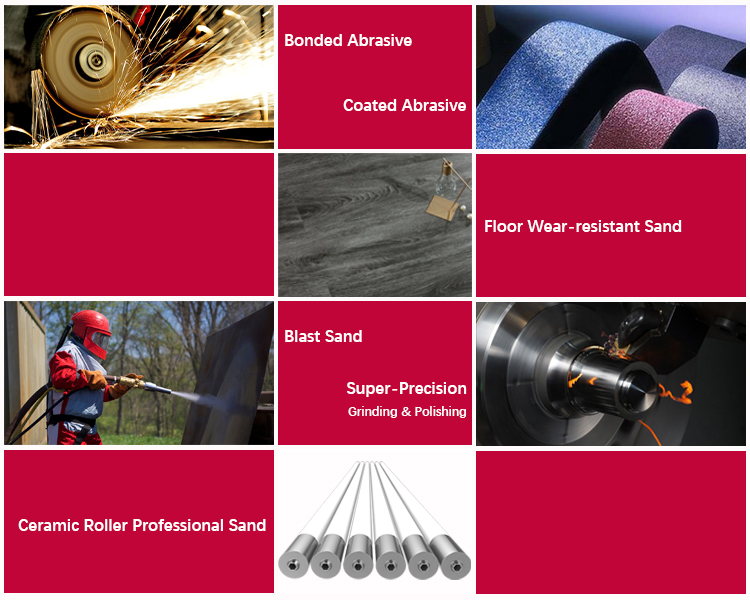

Applications

1. It can be used for coated and coating abrasives, floor wear-resistant sand, ceramic roller professional sand, wet or dry blast sand.

2. It’s uitable for super-precision grinding and polishing in the crystal and electronics industries.

3. It ‘s suitable for processing hardened steel, alloy steel, high-speed steel, high carbon steel and other materials with high hardness and high tensile strength.

4. It can also be used as contact media, insulators and precision casting sand.

Product detail pictures:

Related Product Guide:

We have now numerous great personnel members good at advertising, QC, and working with kinds of troublesome dilemma from the creation course of action for High reputation White Corundum Abrasive - White Fused Alumina for Abrasives – Yufa , The product will supply to all over the world, such as: Pretoria, Uzbekistan, Iraq, The president and all the company members would like to provide qualified goods and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.