High Quality Alpha Calcined Alumina - Low-Sodium Calcined Alumina (HA) Series Coarse Powder – Yufa

High Quality Alpha Calcined Alumina - Low-Sodium Calcined Alumina (HA) Series Coarse Powder – Yufa Detail:

Specification

| Model No. | Chemical Composition (%) | True Density | Apparent Density | Original Crystal | Conversion Rate | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

≥% | |||

| HA5 | 99.5 | 0.05 | 0.02 | 0.12 | 0.1 | 3.95 | 0.9 | 6.5-8.0 | 95 | 1. Unground & Low sodiume 2. Near-spherical crystal 3. Large crystal & Fully developed 4. Less shrinkage & Large output 5. Good quality stability |

1. Suitable for high-performance ceramics 2. Suitable for rough polishing 3. Suitable for refractory materials 4. Suitable for thermal conducting fillers 5. Suitable for wear-resistant coating industries |

| HA4 | 99.5 | 0.05 | 0.02 | 0.10 | 0.1 | 3.95 | 0.9 | 5.5-6.5 | |||

| HA3 | 99.5 | 0.05 | 0.02 | 0.12 | 0.1 | 3.95 | 0.9 | 4.5-5.6 | |||

| HA2 | 99.5 | 0.05 | 0.02 | 0.15 | 0.1 | 3.93 | 0.9 | 3.0-4.0 | 93 | 1. Unground, medium sodium 2. Near-spherical crystal 3. Crystal range of 2-3 μm 4. Good sinterability & Large output 5. Good quality stability. |

Suitable for ceramics and refractory industries. |

| HA1 | 99.7 | 0.05 | 0.02 | 0.01 | 0.1 | 3.93 | 0.9 | ~2 | 93 | 1. Extremely low impurities 2. Na2O≤ 0.01% 3. High conversion rate 4. Fine and uniform crystal |

1. Suitable for high-performance ceramics 2. Suitable for preparation of refractory powder 3. Suitable for wear-resistance coatings industries, etc. |

| HA2X | 99.5 | 0.10 | 0.02 | 0.08 | 0.1 | 3.95 | 0.9 | ~3 | 95 | 1. Easy to grind 2. Extremely low impurities 3. Good crystal sphericity 4. Narrow cystal distribution 5. Less shrinkage & Large output 6. Good quality stability |

1. Suitable for high-performance ceramics 2. Suitable for LCD glass, refractory materials 3. Suitable for thermally conductive fillers 4. Suitable for medium polishing materials industries, etc. |

| HA1X | 99.5 | 0.12 | 0.02 | 0.10 | 0.1 | 3.93 | 0.9 | ~2.3 | 93 | 1. Easy to grind & Low sodium 2. Good sphericity 3. Narrow cystal distribution 4. Small crystal & Good flowability 5. Large output & Good quality stability |

1. Suitable for the production of high-performance ceramics and refractory fine powder 2. It can be used in alumina ball |

| HA0X | 99.5 | 0.08 | 0.02 | 0.10 | 0.1 | 3.9 | 0.9 | ~1 | 92 | 1. Small crystal 2. Low impurities. |

1. Suitable for the production of high-performance ceramics and refractory powder preparation 2. It can used to preparation of wear-resistant coatings industries, etc 3. It can be used in alumina ball |

Application

1. Suitable for high-performance ceramics, rough polishing, refractory materials, thermal conducting fillers and wear-resistant coating industries

2. Suitable for preparation of refractory powder etc.

3. Suitable for LCD glass, thermally conductive fillers, medium polishing materials industries, etc.

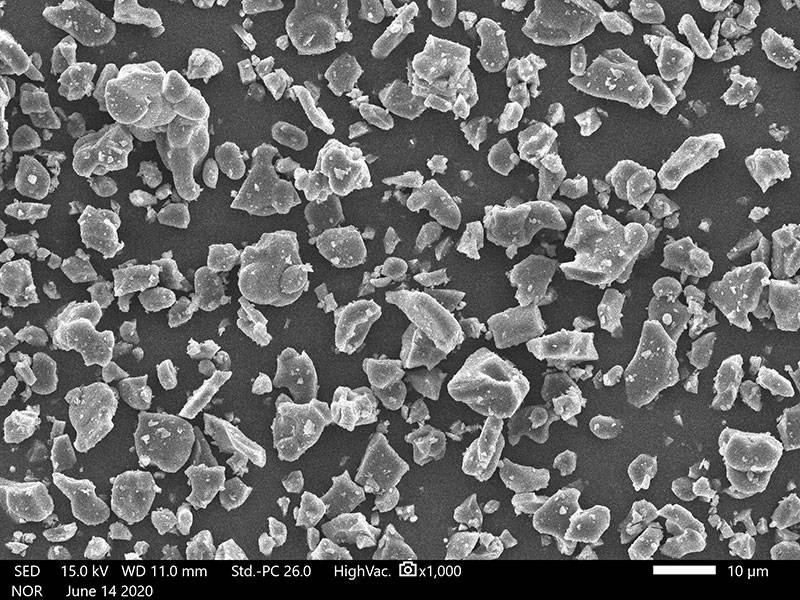

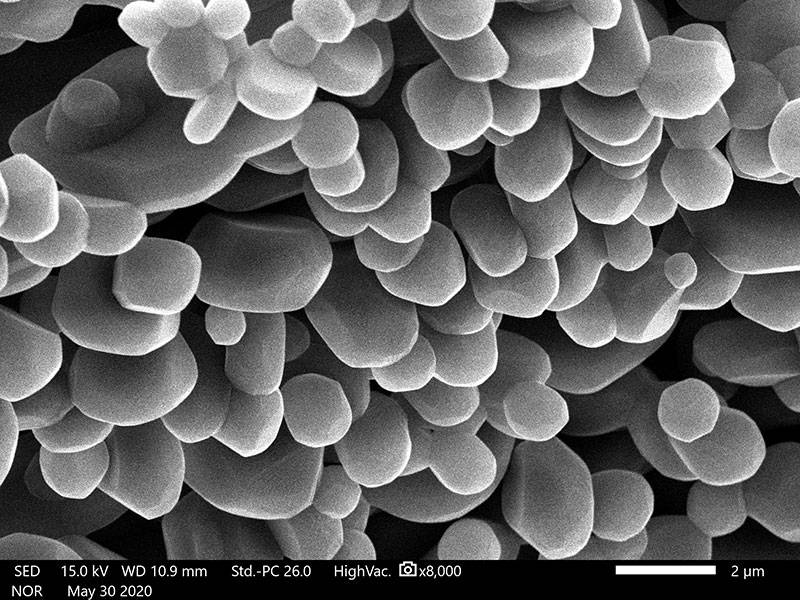

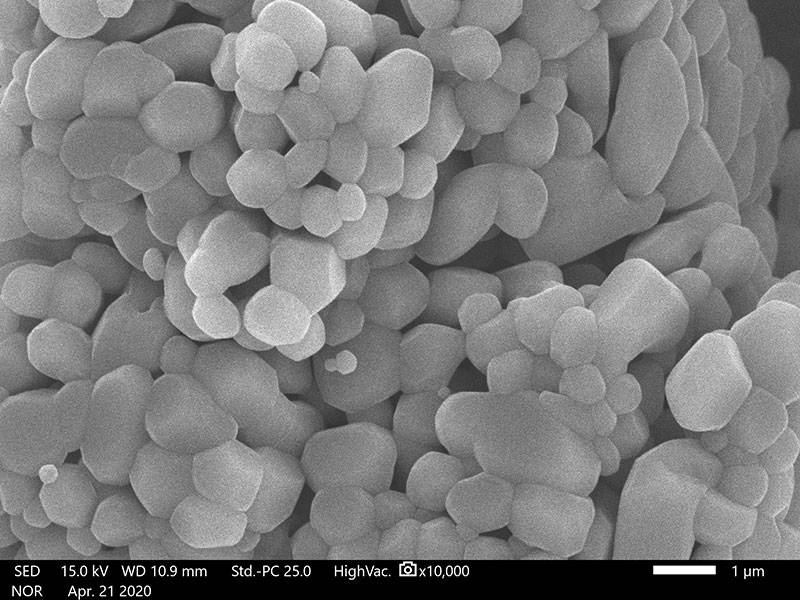

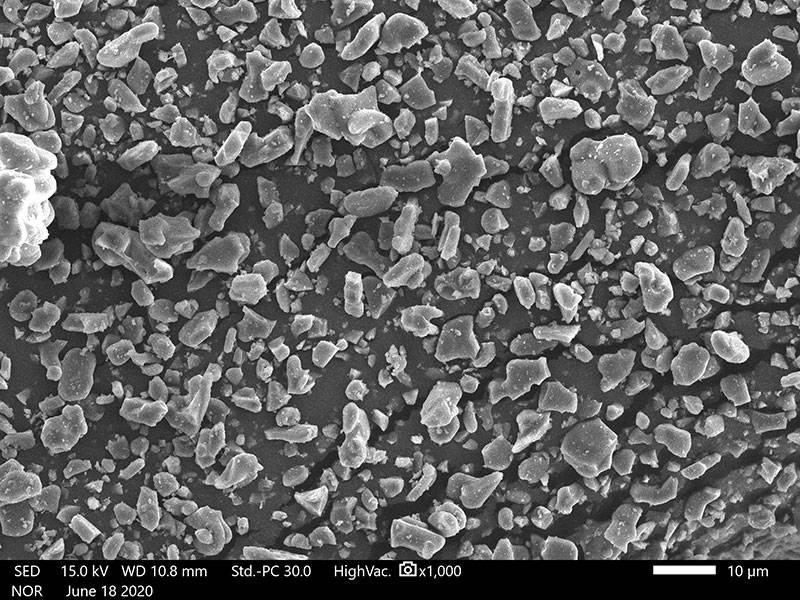

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our organization for your long-term to establish alongside one another with shoppers for mutual reciprocity and mutual benefit for High Quality Alpha Calcined Alumina - Low-Sodium Calcined Alumina (HA) Series Coarse Powder – Yufa , The product will supply to all over the world, such as: Ecuador, United Arab Emirates, Lebanon, We have won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.

A good manufacturers, we have cooperated twice, good quality and good service attitude.

Write your message here and send it to us