Good Quality Alpha Alumina - Low Sodium Calcined Alumina (CA) Series for Ceramics – Yufa

Good Quality Alpha Alumina - Low Sodium Calcined Alumina (CA) Series for Ceramics – Yufa Detail:

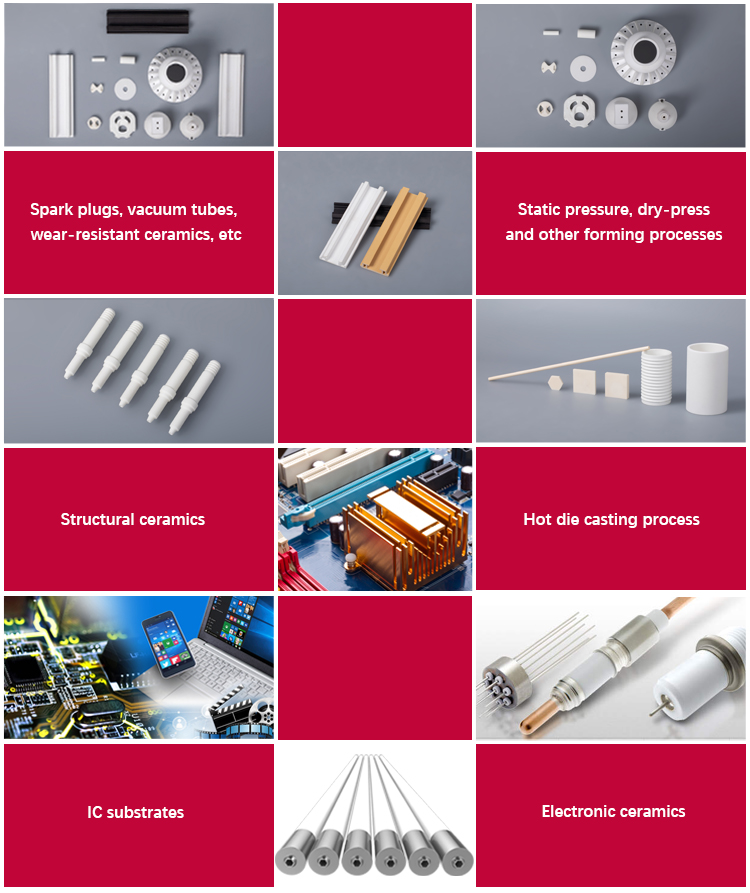

Applications

Specification

| Model No. | Chemical Composition(%) | True Density | Apparent Density | Grain Size D50 | +325 Mesh | Original Crystal D50 | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 ≥ |

g/cm3 > |

D50 (μm) |

<% | D50(μm) | |||

| CA1A | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.97 | >0.95 | ~70 | 5.0-6.0 | 1. High temperature calcination 2. Low sodium 3. Large crystal 4. High conversion rate 5. Stable shrinkage. Good fluidity 6. High insulation performance 7. High mechanical strength |

1. High-performance ceramics, such as vacuum tubes 2. Especially suitable for hot -pressing casting process |

|

| CA1D | 99.5 | 0.05 | 0.03 | 0.08 | 0.1 | 3.95 | >0.90 | 3.0-4.0 | 1. Low sodium 2. Moderate crystal size 3. Good particle size distribution 4. Small shrinkage and stability |

1. Spark plugs 2. Vacuum tubes 3. Wear-resistant ceramics, etc. 4. More suitable for static pressure, dry-pressing and other forming processes |

||

| CA1 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.95 | >0.90 | 3.0-3.8 | 1. Static kiln calcination 2. Low sodium 3. Moderate crystal size 4. Good particle size distribution 5. High porcelain density |

1. Mainly used in electronic ceramics 2. Especially suitable for Hot die casting process |

||

| CA2 | 99.5 | 0.08 | 0.03 | 0.08 | 0.1 | 3.96 | >0.90 | 2.8-3.8 | 1. Low sodium 2. Strict crystal size control 3. Good fluidity 4. Stable shrinkage |

1. Electronic ceramics, structural ceramics 2. Especially suitable for Hot die casting process |

||

| CA2G | 0.15 | >0.90 | 3.0-3.5 | < 3.0 | 1. CA2 full grinding 2. Particle size control stability 3. Low sodium 4. Shrinkage stability |

1. Electronic ceramics 2. Structural ceramics, more suitable for making ceramic rollers |

||||||

| CA3 | 99.5 | 0.05 | 0.03 | 0.04 | 0.1 | 3.96 | >0.85 | ~70 | 2.0-2.6 | 1. Strict control of firing temperature 2. Small crystal size 3. Good particle distribution 4. Pretty-low sodium |

Suitable for electronic ceramics, such as IC substrates | |

| CA3G | 0.1 | 2.4-2.9 | <1.0 | Fully grinding of CA3 | ||||||||

| CA4 | 99.5 | 0.05 | 0.03 | 0.10 | 0.1 | 3.93 | >0.90 | ~70 | 1.0-1.8 | 1. Good activity 2. Low sodium 3. High density after firing 4. Stable shrinkage 5. High mechanical strength |

1. Structural ceramics 2. Electronic ceramics 3. 99 alumina ceramic granulation powder material 4. Suitable for extrusion molding process as well |

|

| CA4G | 0.1 | >0.60 | 1.5-2.2 | <1.0 | Fully grinding of CA4 | |||||||

| CA5 | 99.5 | 0.05 | 0.02 | 0.05 | 0.1 | 3.92 | ~70 | <1.0 | 1. Small & unifrom crystal size 2. Good activity |

99 alumina ceramic hot die casting process, etc | ||

| CA5G | 1-1.3 | <1.0 | 1. Small & unifrom crystal size 2. Good activity 3. Fully grinding 4. Narrow particle size distribution |

Ceramic filter,etc | ||||||||

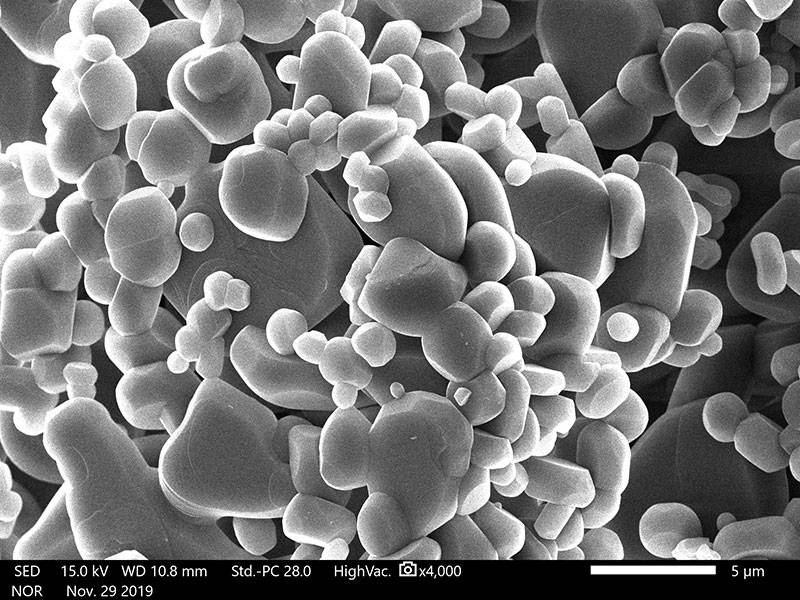

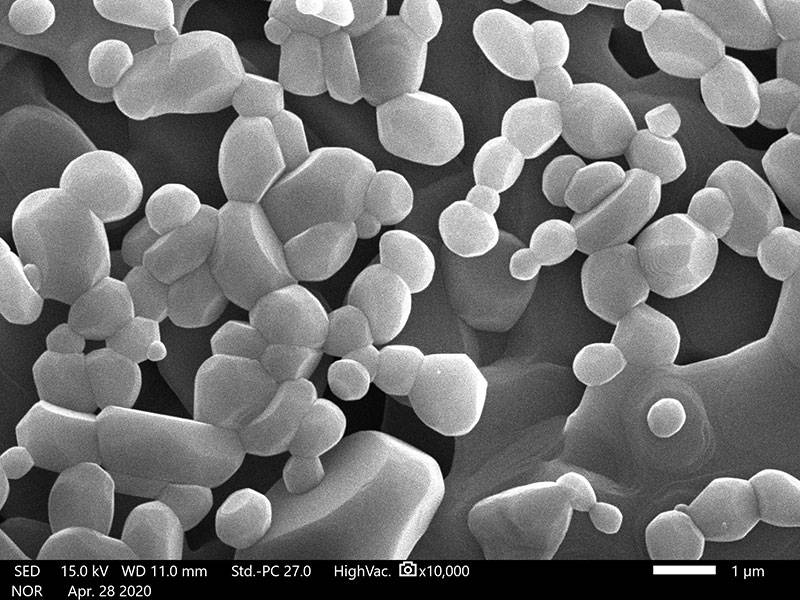

Product detail pictures:

Related Product Guide:

abide by the contract", conforms on the market requirement, joins within the market competition by its superior quality likewise as provides far more comprehensive and great company for shoppers to let them develop into huge winner. The pursue on the corporation, is definitely the clients' gratification for Good Quality Alpha Alumina - Low Sodium Calcined Alumina (CA) Series for Ceramics – Yufa , The product will supply to all over the world, such as: United States, Hungary, Stuttgart, Each product is carefully made, it will make you satisfied. Our merchandise in the production process have got strictly monitored, because it is only to supply you the best quality, we'll feel confident. High production costs but low prices for our long-term cooperation. You can have a variety choices and the value of all types are same reliable. If you have any question, do not hesitate to ask us.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.

Write your message here and send it to us