Fused Mullite

Introduction

Fused Mullite is manufactured by fusing a mixture of high purity Bayer Alumina and pure Quartz in a tilting type arc furnace at a temperature around 2000 deg C. Controlled cooling of the molten mass ensures a high degree of mullitization characterized by well-defined columnar crystals.

Fused Mullite is one of the main raw materials used by the refractory industry for applications requiring thermal shock resistance and corrosion resistance.

The YUFA Group also produces micro sodium mullite with a sodium oxide content of less than 0.1%, and the primary crystal phase is mullite. Due to the reduced sodium oxide content of micro-sodium mullite, its refractoriness, volume density, flexural strength, compressive strength, true density, hardness, etc. are significantly improved compared to Common mullite.

Micro-sodium mullite is mainly used in mullite firing plates, precision casting, high-quality refractory materials and other fields. Our company can produce various specifications of granules and fine powder according to customer needs.

Physical and Chemical Indicators of Common Mullite

|

Chemical Composition Common Mullite |

Grit >0.1mm |

Fine Powder ≤1mm |

|

Al2O3 % |

74-79 |

70-77 |

|

SiO2 % |

20-25 |

22-29 |

|

Fe2O3 % |

≤0.2 |

≤0.3 |

|

CaO % |

0.3 |

0.3 |

|

K2O+Na2O |

≤0.25 |

0.3 |

Chemical Composition of Micro Sodium Mullite:

|

Chemical Composition |

Al2O3 % |

SiO2 % |

Na2O % |

Fe2O3 % |

Loss on Ignition(LOI) % |

|

Micro Sodium mullite |

75-80 | 20-25 | <0.1 | ≤0.1 | ≤0.1 |

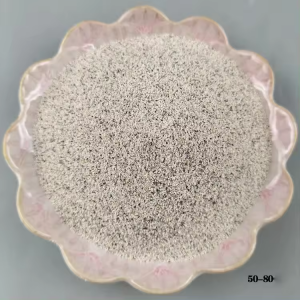

Grain Sizes

Sand section(Grits): 0-1mm / 1-3mm/ 3-5mm 5-8mm...

Fine powder: 180#-0 320#-0...

Product Features

◆ Low Thermal Expansion, Expand evenly

◆ Needle-like crystals are well crystallized

◆ Good Chemical Stability

◆ High flexural strength

◆ Excellent Deformation Stability

◆ Excellent Thermal Shock

◆ Corrosion Resistance

◆ Low Porosity, low residual carbon

◆ Relative Light, High hardness

◆ Oxidation Resistance

◆ High Temperature Slag Resistance

◆ Good chemical resistance High load softening point

Product Applications

◆ Low creep hot blast furnace bricks, Sillimanite Bricks, Hot metal torpedo tank lining bricks

◆ High temperature industrial kiln bricks, Glass kiln lining bricks, shed board

◆ Petrochemical industry

◆ For investment casting, for producing refractory materials for steel industry, for producing high-purity mullite glass melting furnace blocks, for kiln furniture and other applications.

◆ Refractory for glass and steel industry

◆ High-purity mullite block, used for hot blast stove in steel industry.

◆ Ceramic kilns petrochemical industry

◆ Glass lining brick kiln

◆ Glass contact refractories

◆ Sagger and shell building materials

◆ Cast housing construction and high-grade ceramic

◆ Spark plug bodies