Factory source Fused Corundum - White Fused Alumina for Refractories – Yufa

Factory source Fused Corundum - White Fused Alumina for Refractories – Yufa Detail:

Grit and Fine Powder

0-0.1mm 0-0.2mm 0-0.5mm 0-1mm 0.5-1mm 1-3mm 3-5mm 5-8mm, 5-10mm, 10-25mm, 100mesh 200mesh 325mesh …

Other spec are available upon request. Low sodium, Micro sodium WFA are both available.

Product Advantages

1. Low sodium and micro sodium WFA can be provided. Na2O can be double 0.

2. Bulk density can really reach 3.6 g/cm3, which can meet needs of various high-grade refractory materials.

3. YUFA spends 24hours non-stopping melting the WFA, using a tilting furnace with a diameter of 6.5m in order to pursue the high-grade and stable quality.

4. Various specifications can be supported.

Applications

MONOLITHIC REFRACTORIES

Ideal materials for the production of large-scale ladle casting materials, high-grade iron trench casting materials, spraying materials, prefabricated parts and other unshaped refractory materials.

SHAPED REFRACTORIES

Corundum bricks, corundum and mullite corundum saggers, refining. The main raw material of various corundum products is corundum porous plug brick, integral spray gun, composite nozzle, high-temperature industrial furnace lining material etc.

1. White corundum powder is widely used in steel, cement, ceramics, petroleum and other industries.

2. It is an ideal raw material for making large-scale ladle castables, medium and high-grade iron trough castables, gunning materials, preforms and other unshaped refractory materials.

3. It is also the main raw material for various corundum products such as corundum bricks, corundum and mullite corundum saggers, corundum porous plugs for refining, integral spray guns and composite nozzles, and high-temperature industrial furnace lining materials.

Chemical Composition

| Chemical Composition |

Grit > 0.1mm |

Typical Value |

Fine Powder ≤ 0.1mm |

Typical Value |

|

Al2O3%≥ |

99.2 |

99.5 |

99 |

99.3 |

|

SiO2%≤ |

0.1 |

0.03 |

0.15 |

0.08 |

|

Fe2O3%≤ |

0.1 |

0.03 |

0.1 |

0.06 |

|

K2O+Na2O%≤ |

0.35 |

0.25 |

0.4 |

0.3 |

|

Apparent Porosity %≤ |

8 |

6 |

||

|

Common Bulk Density g/cm3≥ |

3.6 |

3.65 |

||

|

High Bulk Density g/cm3≥ |

3.68 |

3.72 |

||

|

True Density g/cm3≥ |

3.9 |

3.93 |

3.9 |

3.93

|

Chemical Composition Of Low Sodium, Micro Sodium White Fused Alumina

|

Chemical Composition |

Low Sodium |

Micro Sodium |

||

|

Guarantee Value |

Typical Value |

Guarantee Value |

Typical Value |

|

|

Na2O % ≤ |

0.15 |

0.08 |

0.08 |

0.02 |

|

Al2O3 % ≥ |

99.4 |

99.7 |

99.6 |

99.8 |

|

SiO2 % ≤ |

0.1 |

0.05 |

0.1 |

0.05 |

|

Fe2O3 % ≤ |

0.05 |

0.02 |

0.05 |

0.02

|

Particle Size Composition Standard

| Specification |

Coarse Grain |

Basic Grain |

Fine Grain |

||

|

Mesh Size (mm) |

Mass Percent Of Oversize (%) |

Mass Percent (%) |

Mesh Size(mm) |

Mass Percent Of Undersize (%) |

|

| 25 ~ 15 |

20 |

≤ 8 |

83 |

115 |

≤ 9 |

| 15 ~ 10 |

15 |

110 |

|||

| 8 ~ 5 |

8 |

5 |

|||

| 5 ~ 3 |

5 |

3 |

|||

| 3 ~ 1 |

3 |

1 |

|||

| 1 ~ 0 |

1 |

0.075 |

≤ 10 |

||

| 1 ~ 0.5 |

0.5 |

≤ 9 |

|||

| 1 ~ 0.3 |

0.3 |

||||

| 0.5 ~ 0 |

0.5 |

67 |

0.075 |

≤ 25 |

|

| 0.3 ~ 0 |

0.3 |

82 |

0.045 |

≤ 10 |

|

| 0.2 ~ 0 |

0.2 |

77 |

≤ 15 |

||

| 0.088 ~ 0 |

0.09 |

≤ 10 |

90 |

|

|

| 0.074 ~ 0 |

0.075 |

|

|

||

| 0.044 ~ 0 |

0.045 |

||||

Note: Various section sand and fine powder can be processed according to customer needs

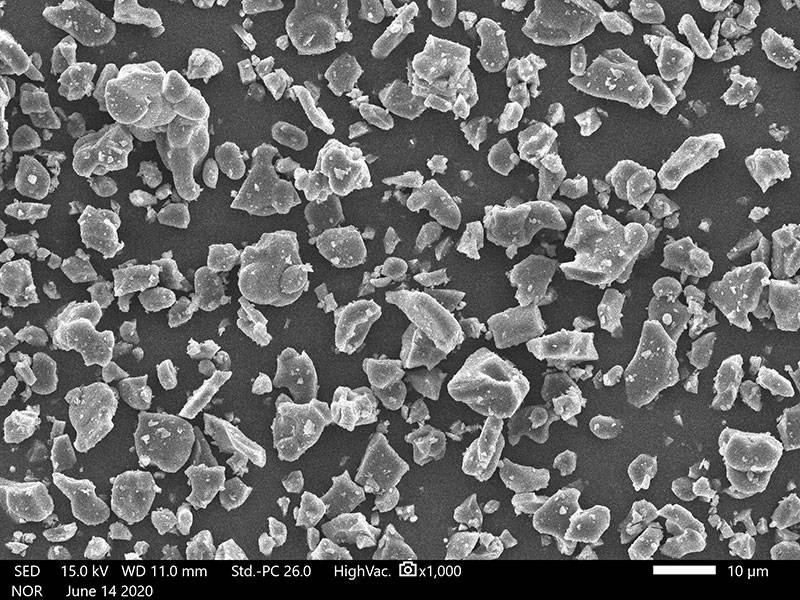

Product detail pictures:

Related Product Guide:

Attaining consumer satisfaction is our company's purpose without end. We will make wonderful endeavours to produce new and top-quality merchandise, satisfy your exclusive requirements and supply you with pre-sale, on-sale and after-sale services for Factory source Fused Corundum - White Fused Alumina for Refractories – Yufa , The product will supply to all over the world, such as: Pakistan, Peru, Accra, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work whole-heartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.