Factory source Fused Corundum - WFA for Refractories – Yufa

Factory source Fused Corundum - WFA for Refractories – Yufa Detail:

Applications

1. White corundum powder is widely used in steel, cement, ceramics, petroleum and other industries.

2. It is an ideal raw material for making large-scale ladle castables, medium and high-grade iron trough castables, gunning materials, preforms and other unshaped refractory materials.

3. It is also the main raw material for various corundum products such as corundum bricks, corundum and mullite corundum saggers, corundum porous plugs for refining, integral spray guns and composite nozzles, and high-temperature industrial furnace lining materials.

Grit and Fine Powder

0-0.1mm 0-0.2mm 0-0.5mm 0-1mm 0.5-1mm 1-3mm 3-5mm 5-8mm, 5-10mm, 10-25mm, 100mesh 200mesh 325mesh …

Other spec are available upon request. Low sodium, Micro sodium WFA are both available.

Product Advantages

1. Low sodium and micro sodium WFA can be provided. Na2O can be double 0.

2. Bulk density can really reach 3.6 g/cm3, which can meet needs of various high-grade refractory materials.

3. YUFA spends 24hours non-stopping melting the WFA with a diameter of 6.5m in order to pursue the high-grade and stable quality.

4. Various specifications can be supported.

Chemical Composition

|

Chemical Composition |

Grit > 0.1mm |

Typical Value |

Fine Powder ≤ 0.1mm |

Typical Value |

|

Al2O3%≥ |

99.2 |

99.5 |

99 |

99.3 |

|

SiO2%≤ |

0.1 |

0.03 |

0.15 |

0.08 |

|

Fe2O3%≤ |

0.1 |

0.03 |

0.1 |

0.06 |

|

K2O+Na2O%≤ |

0.35 |

0.25 |

0.4 |

0.3 |

|

Apparent Porosity %≤ |

8 |

6 |

||

|

Common Bulk Density g/cm3≥ |

3.6 |

3.65 |

||

|

High Bulk Density g/cm3≥ |

3.68 |

3.72 |

||

|

True Density g/cm3≥ |

3.9 |

3.93 |

3.9 |

3.93 |

Chemical Composition Of Low Sodium, Micro Sodium White Fused Alumina

|

Chemical Composition |

Low Sodium |

Micro Sodium |

||

|

Guarantee Value |

Typical Value |

Guarantee Value |

Typical Value |

|

|

Na2O % ≤ |

0.15 |

0.08 |

0.08 |

0.02 |

|

Al2O3 % ≥ |

99.4 |

99.7 |

99.6 |

99.8 |

|

SiO2 % ≤ |

0.1 |

0.05 |

0.1 |

0.05 |

|

Fe2O3 % ≤ |

0.05 |

0.02 |

0.05 |

0.02 |

Particle Size Composition Standard

| Specification |

Coarse Grain |

Basic Grain |

Fine Grain |

||

|

Mesh Size (mm) |

Mass Percent Of Oversize (%) |

Mass Percent (%) |

Mesh Size(mm) |

Mass Percent Of Undersize (%) |

|

| 25 ~ 15 |

20 |

≤ 8 |

83 |

115 |

≤ 9 |

| 15 ~ 10 |

15 |

110 |

|||

| 8 ~ 5 |

8 |

5 |

|||

| 5 ~ 3 |

5 |

3 |

|||

| 3 ~ 1 |

3 |

1 |

|||

| 1 ~ 0 |

1 |

0.075 |

≤ 10 |

||

| 1 ~ 0.5 |

0.5 |

≤ 9 |

|||

| 1 ~ 0.3 |

0.3 |

||||

| 0.5 ~ 0 |

0.5 |

67 |

0.075 |

≤ 25 |

|

| 0.3 ~ 0 |

0.3 |

82 |

0.045 |

≤ 10 |

|

| 0.2 ~ 0 |

0.2 |

77 |

≤ 15 |

||

| 0.088 ~ 0 |

0.09 |

≤ 10 |

90 |

|

|

| 0.074 ~ 0 |

0.075 |

|

|

||

| 0.044 ~ 0 |

0.045 |

||||

Note: Various section sand and fine powder can be processed according to customer needs

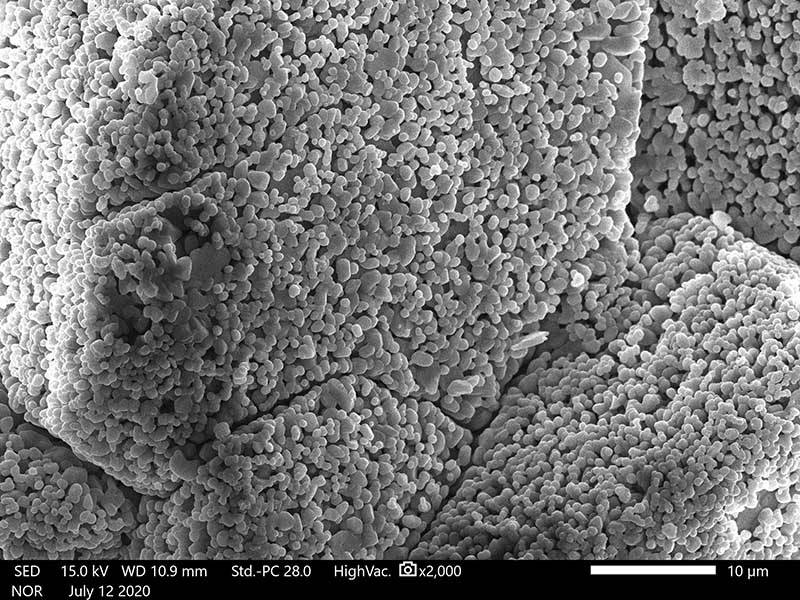

Product detail pictures:

Related Product Guide:

No matter new customer or previous client, We believe in prolonged time period and trustworthy relationship for Factory source Fused Corundum - WFA for Refractories – Yufa , The product will supply to all over the world, such as: Bangladesh, belarus, Latvia, On today, we've got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the highest quality products with best price. We've been looking forward to doing business with you!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!