Ready To Press (RTP)Alumina For Alumina Ceramics

Applications

Specification

Overview:

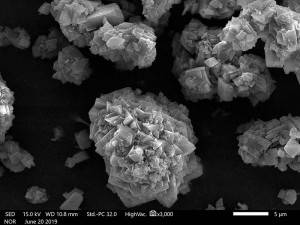

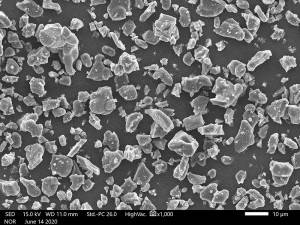

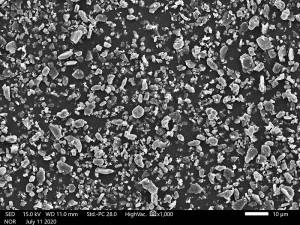

Select high-purity, suitable particle size alumina, and use pressure or centrifugal spray granulation. The powder particles have good gradation, good fluidity, high strength, not easy to break, and stable shrinkage. Porcelain forming temperature is low and density is high. Suitable for dry pressing, rapid stamping, isostatic pressing and other processes. It can be used to produce more than 99% alumina ceramics.

| Model No./Features | YF-997 | YF-99D | YF-95D | YF-95S |

| Alumina content(%) | ≥ 99 | ≥ 99 | ≥ 95 | ≥ 95 |

| Original particle size(μm) | ~ 1.5 | 1.0-1.6 | ~ 3 | ~ 3 |

| Bulk Density (g/cm3) | ≥1.1 | ≥1.05 | ≥1.15 | ≥1.15 |

| Porcelain density (g/cm3) | ≥3.90 | ≥3.87 | ≥3.70 | ≥3.70 |

| Porcelain temperature(℃) | ~ 1710 | ~ 1680 | ~ 1670 | ~ 1670 |

| Porcelain shrinkage | 1.21 | 1.21 | 1.17−1.18 | 1.17−1.18 |

| Appearance Color | White | Yellow | White | White |

| Granulated powder moisture(%) | ≤ 0.5 | ≤ 0.4 | ≤ 0.35 | ≤ 0.35 |

| field of application | For making 997 alumina porcelain | For making 99 alumina porcelain | Making 95 alumina porcelain, suitable for isostatic pressing and dry pressing | Making 96 alumina porcelain, suitable for dry pressing |

Write your message here and send it to us