Calcined Alumina (RA) Series for Refractory Materials

Applications

Specification

| Model No. | Chemical Composition(%) | Apparent Density | Grain Size | +325 Mesh | Original Crystal | Features | Recommended Applications | ||||

| Al2O3 ≥% |

SiO2 ≤% |

Fe2O3 ≤% |

Na2O ≤% |

LOI ≤% |

g/cm3 > |

D50 (μm) |

<% | D50(μm) | |||

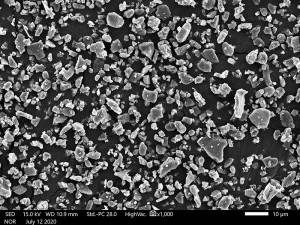

| RA1G | 99.5 | 0.15 | 0.04 | 0.08 | 0.1 | 0.7 | 1.5-2.2 | 0.5 | ~1.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

Used to produce various high-end refractory materials |

| RA2GL | 99.5 | 0.15 | 0.04 | 0.08 | 0.1 | 0.75 | 2.2-2.7 | 1 | ~2.2 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Good particle size distribution 5. High activity |

|

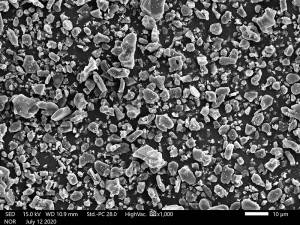

| RA2G | 99.5 | 0.15 | 0.04 | 0.08 | 0.1 | 0.8 | 3.0-3.6 | 1 | 2.5-3.0 | 1. Fully grinding 2. Low sodium 3. Small primary crystal size 4. Reasonable particle size distribution 5. Certain activity |

|

| RA370 | 99.5 | 0.08 | 0.04 | 0.08 | 0.1 | 0.9 | 2.2-2.6 | 0.5 | / | 1. Bimodal particle size distribution 2. Low Sodium 3. Good ffowability 4. Have certail reactivity

|

|

| RA3GD | 99.5 | 0.08 | 0.04 | 0.06 | 0.1 | 0.85 | 4.0-5.0 | 1 | 4.0-4.5 | 1. Grinding, low sodium 2. High calcination temperature 3. Moderate primary crystal size 4. Good fluidity 5. Large bulk density |

|

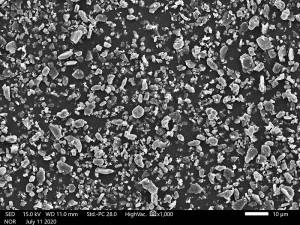

| RA3G | 99.5 | 0.15 | 0.05 | 0.15 | 0.1 | 0.85 | 4.0-5.0 | 1 | 4.0-4.5 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Moderate primary crystal size 5. Good fluidity 6. Large bulk density |

|

| RA5G | 99.5 | 0.15 | 0.05 | 0.12 | 0.1 | 0.95 | 5.0-6.0 | 1 | 5.0-6.0 | 1. Grinding 2. Medium sodium 3. High calcination temperature 4. Large primary crystal size 5. Good flowability 6. Large bulk density |

|

Write your message here and send it to us