Best quality Dense Fused Alumina Material - Fused Dense Corundum – Yufa

Best quality Dense Fused Alumina Material - Fused Dense Corundum – Yufa Detail:

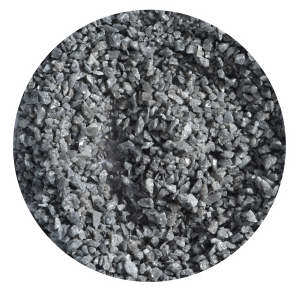

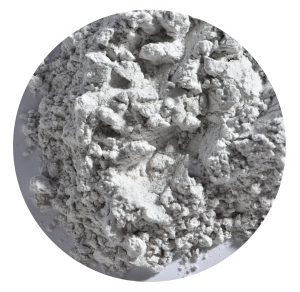

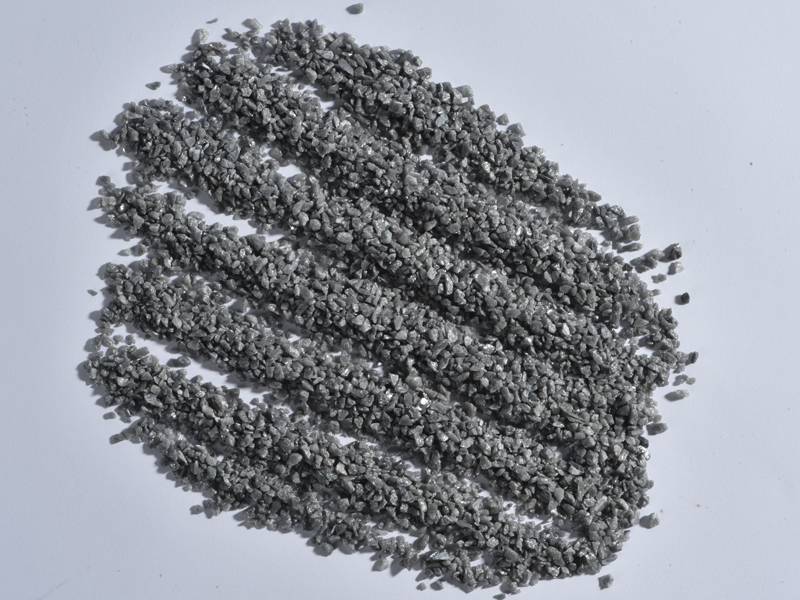

Grit and Fine Powder

0.1-0 mm, 0.2-0 mm, 0.5-0 mm, 1-0 mm, 1-0.5 mm, 3-1 mm, 5-3 mm, 8-5 mm, 10-5 mm, 25-10 mm, 100 mesh, 200 mesh, 325 mesh ……

Other spec are available upon request.

Product Advantages

1. Select high-quality industrial alumina, which is high purity, low impurities. YUFA control quality from raw materials.

2. Fused dense alumina has a high melting point and a high-volume density, which melted at high temperature and constant temperature in an advanced electric melting tilting furnace.

Melting Process

Tilting Furnace – Transfert – Cool Down – Barmac Crusher & Sorting – Sand Making – Warehouse

QC

To the fused dense corundum, the chemical composition of Al2O3, SiO2, Fe2O3, K2O, Na2O need to be tested, also very strick with the inspection of the bulk density.

Applications

MONOLITHIC REFRACTORIES

Ideal material for unshaped refractories, such as tapping trough of blast furnace, castables for ladle, ramming mix, prefabricated parts etc.

SHAPED REFRACTORIES

Ideal material for shaped refractories, such as long nozzle, submerged entry nozzle, stopper, porous brick and nozzle seating brick, etc.

The Fused Dense Corundum is one of the first-choice raw materials for the production of high-performance unshaped and shaped refractory materials.

1. It’s widely used in industries such as steel, cement, ceramics, petrochemicals, etc.

2. It’s main raw materials for making blast furnace iron trough castables, ladle castables, ramming materials, preforms and other unshaped refractory materials.

3. It’s an ideal raw materials for various shaped products such as three continuous casting pieces, air bricks, nozzle block bricks, etc.

4. It’s also an excellent material for making steel-making long nozzles, skateboards and various corundum bricks.

Chemical Composition

|

Chemical Composition |

Grit > 0.1mm |

Typical Value |

Fine Powder ≤ 0.1mm |

Typical Value |

|

Al2O3%≥ |

99.2 |

99.6 |

99 |

99.4 |

|

SiO2%≤ |

0.5 |

0.4 |

0.7 |

0.5 |

|

Fe2O3%≤ |

0.1 |

0.03 |

0.1 |

0.05 |

|

TiO2%≤ |

0.1 |

0.05 |

0.1 |

0.05 |

|

CaO%≤ |

||||

|

MgO%≤ |

||||

|

Na2O%≤ |

||||

|

C%≤ |

0.08 |

0.12 |

0.1 |

|

|

Apparent porosity %≤ |

2 |

0.8 |

2 |

0.8 |

|

Bulk Density g/cm3≥ |

3.9 |

3.93 |

||

|

True Density g/cm3≥ |

3.96 |

3.99 |

3.96 |

3.98 |

Product detail pictures:

Related Product Guide:

Our advantages are lessen charges,dynamic income team,specialized QC,sturdy factories,premium quality services for Best quality Dense Fused Alumina Material - Fused Dense Corundum – Yufa , The product will supply to all over the world, such as: Karachi, Danish, Georgia, Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.